Kahn's USDM 2JZGTE swap thread (aka The "Not Easy" Way)

#886

Lexus Champion

iTrader: (10)

If it isn't bottomed out I would think it is fine, but if it is making noises it is probably bottoming out.

I would get it put at the right length while it is out, and they can look over the joints and lube it up also etc... if they have never been touched before.

If the front tube is the same diameter all the way through, its probably a simple chop out the extra, weld up the halves and re balance.

If the front tube has a part where the diameter bulges out, they might have to replace the front tube and weld on the yoke, either way its a one day job at most shops.

You can probably tell them most of it over the phone and just physically drop it off with any luck.

Seems like you just need the length of the dust shield plus like another 1/4". Measure and remeasure, but being a slip joint there you should probably be ok.

I would get it put at the right length while it is out, and they can look over the joints and lube it up also etc... if they have never been touched before.

If the front tube is the same diameter all the way through, its probably a simple chop out the extra, weld up the halves and re balance.

If the front tube has a part where the diameter bulges out, they might have to replace the front tube and weld on the yoke, either way its a one day job at most shops.

You can probably tell them most of it over the phone and just physically drop it off with any luck.

Seems like you just need the length of the dust shield plus like another 1/4". Measure and remeasure, but being a slip joint there you should probably be ok.

#887

If it isn't bottomed out I would think it is fine, but if it is making noises it is probably bottoming out.

I would get it put at the right length while it is out, and they can look over the joints and lube it up also etc... if they have never been touched before.

If the front tube is the same diameter all the way through, its probably a simple chop out the extra, weld up the halves and re balance.

If the front tube has a part where the diameter bulges out, they might have to replace the front tube and weld on the yoke, either way its a one day job at most shops.

You can probably tell them most of it over the phone and just physically drop it off with any luck.

Seems like you just need the length of the dust shield plus like another 1/4". Measure and remeasure, but being a slip joint there you should probably be ok.

I would get it put at the right length while it is out, and they can look over the joints and lube it up also etc... if they have never been touched before.

If the front tube is the same diameter all the way through, its probably a simple chop out the extra, weld up the halves and re balance.

If the front tube has a part where the diameter bulges out, they might have to replace the front tube and weld on the yoke, either way its a one day job at most shops.

You can probably tell them most of it over the phone and just physically drop it off with any luck.

Seems like you just need the length of the dust shield plus like another 1/4". Measure and remeasure, but being a slip joint there you should probably be ok.

I'm picking up a new center bearing locking nut and two new washers at my dealer tomorrow and then I can get the new center bearing installation finished (or should I leave it off if the driveshaft will be worked on?).

I agree with you. It is probably best to just deal with it now and get it shortened. There was never noise before but there is now. And bottoming out might also explain the old center bearing sagging a bit but without any sign of cracking, brittleness or breakage in the rubber.

Actually they would need both the front and rear driveshaft for any balancing, correct?

Since it’s an MKIII R154 front Driveshaft it does bulge some in the middle unlike an SC or Soarer front driveshaft.

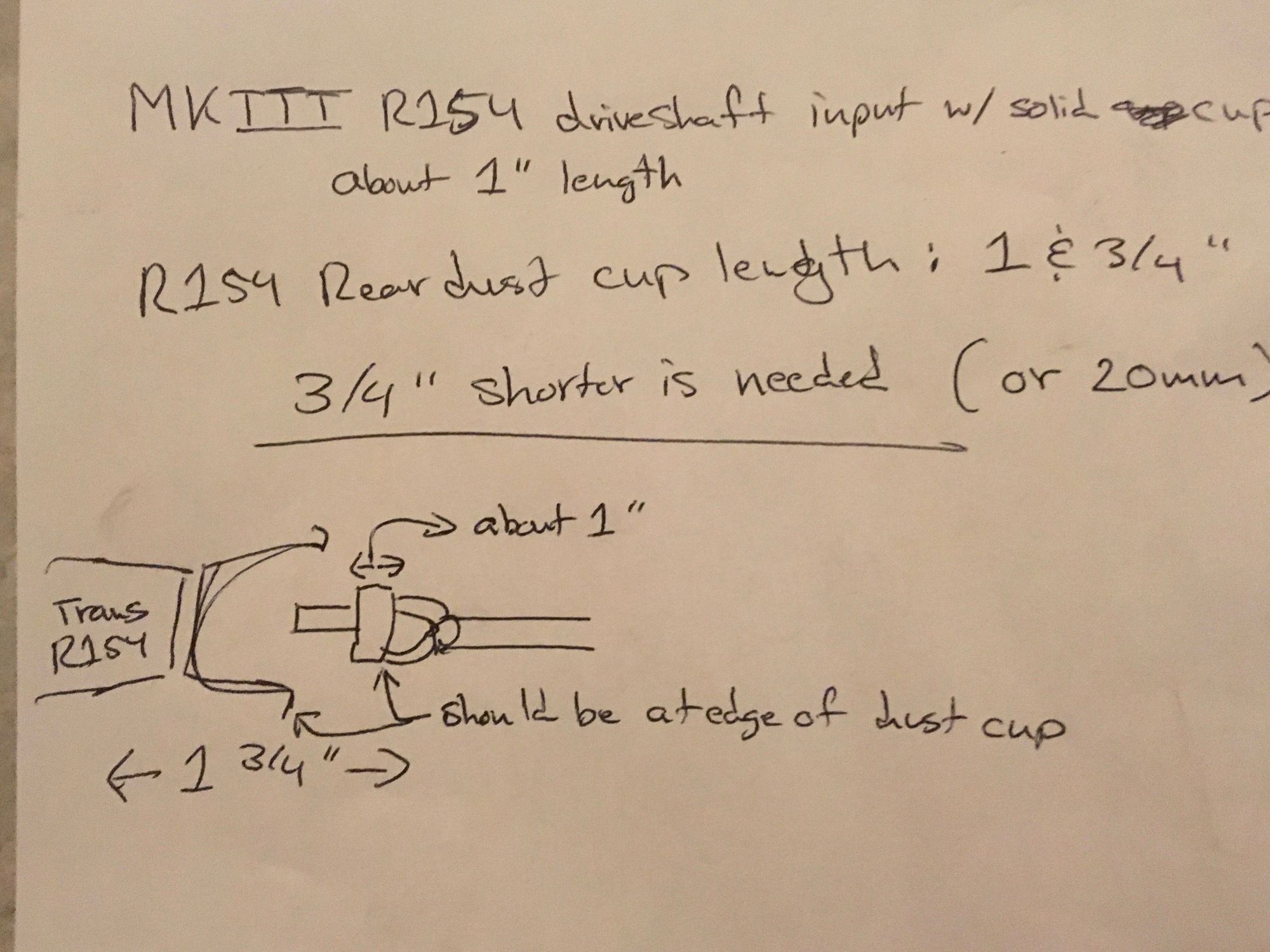

By my many measurements that I’ve gone over and over I keep coming back to making the driveshaft 3/4” shorter to get the trans rear dust shield (which I’ve had removed for years) aligned like this with the front driveshaft’s integrated “cup”.

In another thread I researched someone else with a Supra or SC and an MKIII R154 front driveshaft also stated that 3/4” / 0.78” / 20mm was also his solution to making it right.

...

Would you say that this is image below shows what a factory configured front driveshaft is supposed to look like back there, Ali? This is the goal that I’ve based my measurements on.

(example image not mine; R154 in an MKII Supra with some truck d/s that happened to fit that car. Only reposting to focus on the front driveshaft length at the trans)

This next image is what my MKIII R154 front driveshaft engagement has looked like for many years now. No odd noises until I re-installed my TT Auto diff. And oddly that is the diff I had been running for many years before I took down my car for the engine swap a couple of years back. I had the same rear diff in the car (when it still had 4.27 gears inside it) when I first started driving on the 2JZ-GTE. At that time, no issues. Also no noise or binding issues when the temporary SC400 3.92 open diff was swapped in.

This only cropped up right after I re-installed the newly rebuilt TT Auto diff.

Still, if I wasn’t bottoming out before I probably was within millimeters of doing so all along.

Note that the R154's rear cup is removed. It has been like that since 2013. The original one got damaged the first time this driveshaft was installed. I have another brand new dust cup to re-install on the R154 but have never used it.

Last edited by KahnBB6; 04-10-20 at 02:16 AM.

#888

Lexus Champion

iTrader: (10)

The new center bearing might lift it a hair and help out, but they all sort of sag some with the weight of the shaft on them bolted up, but it'll get bad when they are worn out so that could be part of it.

With the bulge they are probably going to retube the front and reuse the ends, but it might vary so see what they say.

I am not sure if they re-balance the entire thing together or the 2 halves separately on the ones with carrier bearings, I have normally taken the whole driveshaft and let them sort it out.

I wonder how much depth there is in the trans for the slip yoke, otherwise it just seems like you could trim 1/4" off the integrated dust cup and call it a day if that is what is bottoming out.

Otherwise, yes it does look like it needs to go back some for the extra dust cap to fit on there and still have a good amount of space.

You will be reducing the amount of slip yoke that goes into the transmission though by 3/4". IT should be fine but you don't want to go too far.

I think it would be a personal call to take a little more off your integrated dust cap, you could grind off 1/4" with a dremel and be good it looks like.

But I know you like that originality, so I think the other way would be to modify it to the right length, but it won't be a r154 driveshaft at that point it would be custom.

I would probably just trim the 1/4" off the integrated one and let it have more spline engagement as long as the splines aren't bottoming out inside.

Do you still have your old or original driveshaft laying around? that one might be easier to modify then you could always have this one as a spare with the dust cap trimmed another 1/4".

Is it just me or does the celica driveshaft pic above look like a smaller size U joint than your's on the SC, so it seems there are some differences but hopefully the dust cap should be similar.

With the bulge they are probably going to retube the front and reuse the ends, but it might vary so see what they say.

I am not sure if they re-balance the entire thing together or the 2 halves separately on the ones with carrier bearings, I have normally taken the whole driveshaft and let them sort it out.

I wonder how much depth there is in the trans for the slip yoke, otherwise it just seems like you could trim 1/4" off the integrated dust cup and call it a day if that is what is bottoming out.

Otherwise, yes it does look like it needs to go back some for the extra dust cap to fit on there and still have a good amount of space.

You will be reducing the amount of slip yoke that goes into the transmission though by 3/4". IT should be fine but you don't want to go too far.

I think it would be a personal call to take a little more off your integrated dust cap, you could grind off 1/4" with a dremel and be good it looks like.

But I know you like that originality, so I think the other way would be to modify it to the right length, but it won't be a r154 driveshaft at that point it would be custom.

I would probably just trim the 1/4" off the integrated one and let it have more spline engagement as long as the splines aren't bottoming out inside.

Do you still have your old or original driveshaft laying around? that one might be easier to modify then you could always have this one as a spare with the dust cap trimmed another 1/4".

Is it just me or does the celica driveshaft pic above look like a smaller size U joint than your's on the SC, so it seems there are some differences but hopefully the dust cap should be similar.

Last edited by Ali SC3; 04-10-20 at 08:25 AM.

The following users liked this post:

KahnBB6 (04-10-20)

#889

The new center bearing might lift it a hair and help out, but they all sort of sag some with the weight of the shaft on them bolted up, but it'll get bad when they are worn out so that could be part of it.

With the bulge they are probably going to retube the front and reuse the ends, but it might vary so see what they say.

I am not sure if they re-balance the entire thing together or the 2 halves separately on the ones with carrier bearings, I have normally taken the whole driveshaft and let them sort it out.

I wonder how much depth there is in the trans for the slip yoke, otherwise it just seems like you could trim 1/4" off the integrated dust cup and call it a day if that is what is bottoming out.

Otherwise, yes it does look like it needs to go back some for the extra dust cap to fit on there and still have a good amount of space.

You will be reducing the amount of slip yoke that goes into the transmission though by 3/4". IT should be fine but you don't want to go too far.

I think it would be a personal call to take a little more off your integrated dust cap, you could grind off 1/4" with a dremel and be good it looks like.

But I know you like that originality, so I think the other way would be to modify it to the right length, but it won't be a r154 driveshaft at that point it would be custom.

I would probably just trim the 1/4" off the integrated one and let it have more spline engagement as long as the splines aren't bottoming out inside.

Do you still have your old or original driveshaft laying around? that one might be easier to modify then you could always have this one as a spare with the dust cap trimmed another 1/4".

Is it just me or does the celica driveshaft pic above look like a smaller size U joint than your's on the SC, so it seems there are some differences but hopefully the dust cap should be similar.

With the bulge they are probably going to retube the front and reuse the ends, but it might vary so see what they say.

I am not sure if they re-balance the entire thing together or the 2 halves separately on the ones with carrier bearings, I have normally taken the whole driveshaft and let them sort it out.

I wonder how much depth there is in the trans for the slip yoke, otherwise it just seems like you could trim 1/4" off the integrated dust cup and call it a day if that is what is bottoming out.

Otherwise, yes it does look like it needs to go back some for the extra dust cap to fit on there and still have a good amount of space.

You will be reducing the amount of slip yoke that goes into the transmission though by 3/4". IT should be fine but you don't want to go too far.

I think it would be a personal call to take a little more off your integrated dust cap, you could grind off 1/4" with a dremel and be good it looks like.

But I know you like that originality, so I think the other way would be to modify it to the right length, but it won't be a r154 driveshaft at that point it would be custom.

I would probably just trim the 1/4" off the integrated one and let it have more spline engagement as long as the splines aren't bottoming out inside.

Do you still have your old or original driveshaft laying around? that one might be easier to modify then you could always have this one as a spare with the dust cap trimmed another 1/4".

Is it just me or does the celica driveshaft pic above look like a smaller size U joint than your's on the SC, so it seems there are some differences but hopefully the dust cap should be similar.

The problem isn't the MKIII R154 driveshaft's integrated dust cup but rather its forward U-joint. Its dust cup fits perfectly into the R154's removable tail housing dust cup. It is the driveshaft's U-joint that was hitting my original R154 rear dust cup and thrashing it out of shape. That's why it was removed in 2013.

But even then engagement clearance was tight. There was some skimming of the R154 rear tail housing metal with the MKIII R154 front driveshaft's dust cup. It wasn't much but it made an awful noise for a couple of weeks when I first got that driveshaft installed.

Then it wasn't an issue for about seven years until now which leads me to believe there was never much slip play clearance to begin with since that driveshaft but perhaps I had JUST enough under most conditions.

In that example picture I posted (which has what I assume is the correct engagement clearance) the driveshaft is from a 4Runner or Tacoma and yes it's U-joints are of a smaller design much like those on a stock SC or Soarer front driveshaft. Also its tubing is uniform and doesn't bulge in the middle like the MKIII driveshaft.

I am going to label and bring along both driveshaft halves for them in evaluate. I'm assuming they will not need the rear rubber donut though so maybe I should remove that temporarily.

Good info about the way center bearings can sag a little with age, thank you. Maybe I really didn't need to remove the old one after all? Well... it'll have a new one now once I get the new crush nut on there.

I'll do that first and then see if this shop can work with me. Worst case if they're unable to at this time (which would be very understandable) I might get another MKIII R154 front driveshaft or SC300 Auto front driveshaft and have them modify that at a later time.... assuming I might be able to get away with this tight clearance driveshaft as is again for the time being.

Whenever I have had everything assembled though there is really very little room for that MKIII R154 front driveshaft to move forward at all. So be it from the cup or the input shaft itself I do think it's bottomed out or else very close to that.

#890

Lexus Champion

iTrader: (10)

I guess I am not understanding exactly what is impacting then, not sure how the u joint hits the dust cap, but as long as you understand it that's good I'm sure you'll find a good solution after a bit.

That is right the w58 is 21 spline keep forgetting, the auto and the R series are usually 23 spline so yeah maybe get an auto one to modify especially if it doesn't have the bulge.. they probably just need to extend it a little bit.

That is right the w58 is 21 spline keep forgetting, the auto and the R series are usually 23 spline so yeah maybe get an auto one to modify especially if it doesn't have the bulge.. they probably just need to extend it a little bit.

#891

I guess I am not understanding exactly what is impacting then, not sure how the u joint hits the dust cap, but as long as you understand it that's good I'm sure you'll find a good solution after a bit.

That is right the w58 is 21 spline keep forgetting, the auto and the R series are usually 23 spline so yeah maybe get an auto one to modify especially if it doesn't have the bulge.. they probably just need to extend it a little bit.

That is right the w58 is 21 spline keep forgetting, the auto and the R series are usually 23 spline so yeah maybe get an auto one to modify especially if it doesn't have the bulge.. they probably just need to extend it a little bit.

The old, torn up R154 rear tailshaft dust shield vs a brand new one (unpainted for the moment).

And a drawing I made for myself and the driveline shop to explain what I wanted to do.

You're right, Ali. I think picking up an SC300 Auto front driveshaft to have modified may be best. In its case, since it's too short it will have to be lengthened by 50mm or 1.96".

I took the MKIII R154 front driveshaft in to my local machinist/driveline shop and they could do the modification for length with all brand new tubing on the front shaft... but they said they did not have the balancing dyno required for an OEM two-piece driveshaft. Instead I'm just having them restore a couple of slightly damaged threads where the center bearing goes on (a previous mechanic's bad work).

The local shop could also build and balance for me a custom one-piece driveshaft if I were to provide them with the 23-spline front slip yoke and the rear diff mating flange but I want to retain the factory design.

I was recommended by them a driveline place about an hour from me in Orlando FL where the length modification and balancing can be done. Although I would have no idea what their ETA will actually be while my SC has no driveshaft. Especially with this corona virus scare going on where I have to be extra careful for the sake of my family.

I also looked up a few other professional driveline/driveshaft shops in other cities as alternatives. I will look into all of them. Every single one of them is a long drive and likely a commitment to drop the parts off and come back when they're done.

I am also considering Fedex shipping for the front and rear driveshaft to whichever of these driveshaft shops will allow me to work with them remotely. But it may be that they'll want me to come and pick the finished pieces in person even if I ship. That would still be okay as it means only one trip there and back.

...

Especially with the health concerns right now I am considering another option along the lines of what you suggested:

Find an SC300 Auto front driveshaft, another SC300/400 rear driveshaft and send or drive *those* out for the length modification. Then, just reinstall my MKIII R154 front driveshaft as is and hope that the realignment of everything will be okay and not cause any hitting (and that my matchmarks are still visible to maintain the set balance).

It seems like a bad time to risk not having a driveshaft setup that fits to fall back on.

Either way I want to solve the length issue for good but even though it will be extra money for more parts it might be a good bet. And then the R154 front driveshaft is actually worth something used.

Last edited by KahnBB6; 04-11-20 at 12:48 AM.

#892

Lexus Champion

iTrader: (10)

I see now what you are saying with the contact of the dust cap and the yoke/joints. I would probably just trim the integrated cup for a hair more clearance still and call it a day.

If you do decide to modify/make one, I think it makes more sense to not cut up the more expensive mk3 front shaft and modify the sc400 one if they are re-tubing most of the front anyways.

Also if they do modify and you have issues you might end up in a worse situation than just a little contact, so doing it to a spare would be safer.

You might even put that mk3 one back in with the new carrier bearing and not have as much contact as with the worn one, then start working on the sc400 one.

I dunno but it seems if they balanced both sides, they would have balance together to a certain degree but I could see them wanting to do the whole thing at once.

Did you rebalance the whole shaft after putting the mk3 front half on? more or less the same principle.

If you do decide to modify/make one, I think it makes more sense to not cut up the more expensive mk3 front shaft and modify the sc400 one if they are re-tubing most of the front anyways.

Also if they do modify and you have issues you might end up in a worse situation than just a little contact, so doing it to a spare would be safer.

You might even put that mk3 one back in with the new carrier bearing and not have as much contact as with the worn one, then start working on the sc400 one.

I dunno but it seems if they balanced both sides, they would have balance together to a certain degree but I could see them wanting to do the whole thing at once.

Did you rebalance the whole shaft after putting the mk3 front half on? more or less the same principle.

#893

I never had the MK3 R154 front shaft re-balanced, no. Maybe it was never totally perfect when paired with my SC300's stock rear shaft for that reason. But it always seemed smooth enough to me to be "normal".

Getting any front driveshaft length modified and re-balanced will have to involve the rear driveshaft as well and so I'll need to pick up another one of those from an SC if I am going to reinstall the R154 setup (yet I'm still waiting on my local machine shop to chase and repair the very front of the threads for the new center bearing nut on that MKIII R154 shaft).

To do what you suggest, and which I also think is a good idea, I am going to need to find and buy another 92-00 SC rear driveshaft and a 92-00 SC300 front driveshaft. I don't have spares of either one currently.

Once I have the thread-repaired MKIII R154 front driveshaft back in hand I'll go about trimming that collar and reinstalling it. As you suggest Ali I'll find other SC Auto driveshaft parts to have modified.

Getting any front driveshaft length modified and re-balanced will have to involve the rear driveshaft as well and so I'll need to pick up another one of those from an SC if I am going to reinstall the R154 setup (yet I'm still waiting on my local machine shop to chase and repair the very front of the threads for the new center bearing nut on that MKIII R154 shaft).

To do what you suggest, and which I also think is a good idea, I am going to need to find and buy another 92-00 SC rear driveshaft and a 92-00 SC300 front driveshaft. I don't have spares of either one currently.

Once I have the thread-repaired MKIII R154 front driveshaft back in hand I'll go about trimming that collar and reinstalling it. As you suggest Ali I'll find other SC Auto driveshaft parts to have modified.

#894

Pole Position

I think you've got a good plan here Craig. We're lucky to have a few really great driveshaft/gear shops in town that can help make those tough decisions. Do you have some guys locally that, when things simmer down, you can go in and ask advice? Even emailing them some photos, measurements, and describing your issue may go a long way in getting things sorted once and for all.

#895

Lexus Champion

iTrader: (10)

That's what I was getting at, you didn't have an issue because both halves are probably balanced from factory.

So if you make a new front half, and balance it alone, and bolt it on I think you would be close enough to neutral just like before.

I don't think balancing the whole thing together is very common or necessary in the grand scheme of things unless the rear portion took a hit that knocked it out of balance which would be obvious.

So you could just get an auto front shaft, modify and balance it and when the time comes just swap out the front.

You've been installing so many nice parts on the car which adds up so I wouldn't waste any extra coin on parts you don't need.

So if you make a new front half, and balance it alone, and bolt it on I think you would be close enough to neutral just like before.

I don't think balancing the whole thing together is very common or necessary in the grand scheme of things unless the rear portion took a hit that knocked it out of balance which would be obvious.

So you could just get an auto front shaft, modify and balance it and when the time comes just swap out the front.

You've been installing so many nice parts on the car which adds up so I wouldn't waste any extra coin on parts you don't need.

#896

I think you've got a good plan here Craig. We're lucky to have a few really great driveshaft/gear shops in town that can help make those tough decisions. Do you have some guys locally that, when things simmer down, you can go in and ask advice? Even emailing them some photos, measurements, and describing your issue may go a long way in getting things sorted once and for all.

That's what I was getting at, you didn't have an issue because both halves are probably balanced from factory.

So if you make a new front half, and balance it alone, and bolt it on I think you would be close enough to neutral just like before.

I don't think balancing the whole thing together is very common or necessary in the grand scheme of things unless the rear portion took a hit that knocked it out of balance which would be obvious.

So you could just get an auto front shaft, modify and balance it and when the time comes just swap out the front.

You've been installing so many nice parts on the car which adds up so I wouldn't waste any extra coin on parts you don't need.

So if you make a new front half, and balance it alone, and bolt it on I think you would be close enough to neutral just like before.

I don't think balancing the whole thing together is very common or necessary in the grand scheme of things unless the rear portion took a hit that knocked it out of balance which would be obvious.

So you could just get an auto front shaft, modify and balance it and when the time comes just swap out the front.

You've been installing so many nice parts on the car which adds up so I wouldn't waste any extra coin on parts you don't need.

Well guys... I definitely agree about not spending more on extra parts that I don't need. And yes, I have asked for a little local advice about this. The concern keeps coming back to having almost no extra slip play clearance and what long term issues that *might* cause under some real world driving conditions. It still is something interesting that I got away with this for so long through multiple clutch changes and two diff change-outs until now.

I got my MKIII R154 front driveshaft back from the local shop today who were able to repair the 24mm-1.5 threads for the locking/stake nut. So that much is done (I'm also giving it a light wipe down with bleach/water mix on a disposable towel and a final wipe with a damp disposable towel to mitigate any possibility of COVID-19 contamination).

However I have made contact with the one driveline shop an hour south of me that was on my list and I like the dialogue the owner and I had to shorten and balance the MKIII front shaft that I already have. And his balancing machine (a Coetz SE200) can handle factory two-piece systems.

It's not located in one of the biggest COVID risk zones although any of us need to be VERY careful going anywhere right now. I think I can show him what I need done with my protection and at a reasonable standing distance. He said it would take maybe 4 business days (M-F range) or so and the reviews on his business seem to point to reliable turnaround times and communication.

...

Though I think you are right about the SC300 rear shaft and MKIII front shaft being independently balanced, Ali. I'm truly not sure if they were ever a totally perfect match together but they have been mostly smooth together except on rough tarmac where my linear rate Hypercoil suspension springs transmit a lot of the road into the chassis. I honestly cannot tell which is which since I have never had a baseline driveshaft balancing done.

It's still difficult to determine what minute shifting caused this issue in the first place (since the SC center bearing and rear driveshaft flange are both bolted down tightly to TSRM spec) but I do know for sure that it is related to having almost none of the factory slip play clearance that Toyota's engineers wanted between their slip yoke driveshafts and any of the R-Series transmissions.

But since I know the clearance is still very tight and since I already have everything out of the car I'm inclined to drive both driveshaft ends over to him to get it done right.

...

If I had considered the potential issue while my engine swap was underway I'd have had this very thing done back then.

It's just not a thing I want to have to do much of (get under the car, pull the driveshaft out yet again for the same issue) or risk long term excessive wear on the transmission itself since there is no extra slip play in this driveshaft.

If I already know that this front driveshaft was intended for a 7M bellhousing which is at least 20mm (3/4") shorter than a 1JZ bellhousing I think it would be hard to go wrong just getting the adjustment done now once and for all.

And Ali, as you say, I would then avoid having a set of extra SC and MKIII driveshaft parts that I will not need.

I think that will be my plan of action tomorrow or the day after.

...

The turbo rebuild and swap install issue on the other hand is something that I can take my time with and do all the work for myself since there is no issue driving the car normally or spiritedly only on the #1 turbo for now.

But this thing with the driveshaft I feel just needs to be corrected for good while all the parts are out and while there is this downtime.

The bottom line is that I need the SC back up and operable again soon. It can't sit indefinitely or potentially have this crop up again the moment I bolt it all back up as is. Also I don't want to and can't afford a chance some driveline related issue due to being maybe 1-2mm within a chance of bottoming or binding.

Especially not in crazy weather Florida or as a pandemic drags on and on for months.

A LOT of people have used the MKIII front driveshaft swap in SC's and MKIV's to good effect so I can only speak to what I've personally observed, measured and determined as a good solution.

Last edited by KahnBB6; 04-14-20 at 06:38 PM.

The following users liked this post:

RudysSC (04-15-20)

#897

Lexus Champion

iTrader: (10)

Yeah I think if you go over it carefully and make the right adjustment you should be fine, you can always get it redone for some reason if it isn't.

Shortening a specific length and re balancing should be pretty straight forward for the shop, its when you take all the measurements on a new shaft things get tricky.

Shortening a specific length and re balancing should be pretty straight forward for the shop, its when you take all the measurements on a new shaft things get tricky.

The following users liked this post:

KahnBB6 (04-15-20)

#898

Yeah I think if you go over it carefully and make the right adjustment you should be fine, you can always get it redone for some reason if it isn't.

Shortening a specific length and re balancing should be pretty straight forward for the shop, its when you take all the measurements on a new shaft things get tricky.

Shortening a specific length and re balancing should be pretty straight forward for the shop, its when you take all the measurements on a new shaft things get tricky.

I dropped the MKIII R154 front shaft (with the SC center bearing) and SC300 rear shaft (with the donut attached) to the shop down south. It's was a small machine shop but they clearly know their stuff and were excellent professionals. I don't think there's a a driveshaft or axle related thing they can't do there.

In this case the owner was confident that the MKIII shaft's tubing with the infamous bulge could be left in while only the small 3/4" is removed from the front tapered section before the U-joints and yoke before welding it up. But to be extra safe he was clear that he wanted both the front and rear sections to make sure everything would balance well.

He may get it done just before the weekend or by early next week. And his ballpark estimate for the modification and re-balancing was only about $200 so long as that existing shaft is good to re-use. Very reasonable

In the meantime I need to primer and paint that new replacement R154 output dust cover. Some more 500F VHT black paint with a 500F VHT clear coat ought to do it.

...

In other news I may finally get my boost gauge inaccuracy fixed if I can get to it this week. I can still work on that while the SC is stationary.

I did some more testing a few days ago after adding a new weather sealed connector going to the boost sender. With my multimeter I tested the output of the sender as well as the raw 12V and Ground signals from the wiring harness.

At ignition ACC and ON settings I found that the signal coming from the sender is still 1.0V as it should be. I also found that the 12V and Ground signals were consistent from those locations.

With this I think I have ruled out any wiring issues on the engine compartment side so I now believe the issue lies with the power source & ground wires to the boost gauge itself. I think that there is a voltage drop in power going into it and possibly that is what is really causing the issue with an inaccurate signal. In other words if the boost gauge (not the sender) is getting a voltage drop slightly below +12V then maybe that is what is causing a 1.0V boost sender signal to get distorted and thus make the In-Hg and PSI readings shift too low on the scale.

I've got a couple more things I will try including a couple of direct wire bypasses from the gauge directly through the open door into the engine compartment but if those tests prove my hypothesis correct then I think the issue may be that I need to give the boost gauge itself a different power source.

If for some reason it is the signal wire that would be pretty weird since it's fully insulated and isn't connected to anything besides the gauge and sender via a long route into the cabin and some connectors (and that signal is always the correct 1.0V at the key's ACC position. It only drops to 0.86V when the key is switched to pre-ignition ON... when more current will be drawn all over the car).

I'll narrow it down perfectly soon.

Last edited by KahnBB6; 04-16-20 at 02:15 AM.

The following users liked this post:

Ali SC3 (04-16-20)

#899

Pole Position

Great news - I'm glad you found someone to get that driveshaft sorted for you! It's such a relief to find professional shops that can do good work when you need it the most.

As for the boost gauge - a voltage drop at the sender certainly makes sense. Let us know what you find! I'm excited for you to get your driveshaft back, turbos back on, and to have that bad boy ready for summer!

As for the boost gauge - a voltage drop at the sender certainly makes sense. Let us know what you find! I'm excited for you to get your driveshaft back, turbos back on, and to have that bad boy ready for summer!

#900

Lexus Champion

iTrader: (10)

That is neat they can get the 3/4 taken off before the bulge, that should be perfect when done and pretty reasonable also for re-balancing both.

I always like going to those shops they have so much fun machinery! And nice progress on the gauge, definitely in to see the results!

I always like going to those shops they have so much fun machinery! And nice progress on the gauge, definitely in to see the results!