Kyle's GS300 2JZGTE Project Reboot

#138

Well just figured I'd throw an update on here before the end of the year, as it's been quite some months since.

The most meaningful change I've made over the past few months is developing a flat shift option with the Haltech. In doing so, I've alleviated one of the most important concerning aspects of making power with the A340E transmission. That is, pushing big power through the shifts. The stock transmission ECU will reduce the throttle position a good bit. But I've gone a step further and reduced timing and ignition during the shift as well, to help further drop the power during the gear change. I'm pretty pleased with the results. I'll gladly admit that I had help with this, and if anyone is interested in implementing something like this, I'm happy to give details as to what worked for me.

I still struggle with fuel delivery utilizing my stock fuel feed system. I have an Aeromotive 340LPH pump. I was thinking the pump wasn't getting enough power to meet it's potential. But after doing a direct wire modification from the battery through a relay, to the pump, I see no noticeable improvement in flow as registered by the AFR gauge and the fuel pressure sensor in the rail. This makes me think it may be either the feed line itself, or the damper - I know these are known to be restrictive on the Supras, perhaps they are on our cars as well. Either way, I'm not going to nickel and dime it any further (I needed to do the power modification anyway), so I'll just budget for a dual-pump and fresh fuel line setup sometime next year.

I did find a few minutes to clean up some plumbing that I hastily hooked up as my fabricator/tuner and I were fabricating the intercooler piping.

One of my most useful changes over the past month or so was the stock stereo tape player input hack. https://www.clublexus.com/forums/gs-...-aux-port.html I spent $15 on a little bluetooth device that transmits the audio from my phone into this input. Sounds quite good! Far superior to the FM-transmitter hack. If you have the original audio, and are able to solder, this is a worthwhile 2 hour time investment.

I'll finish with as close to a beauty shot as this 20 year old can muster. I found a set of wheels priced well and close enough to not pass up. Being the geek that I am, I can tell you that these 18X10 wheels with 265/35 and 285/35 tires weigh 3 and 6 lbs heavier than the stock wheels with the 215 series all-seasons. Not bad, IMO. And they look okay too, although certainly not as fancy as some.

Happy Holidays, all

The most meaningful change I've made over the past few months is developing a flat shift option with the Haltech. In doing so, I've alleviated one of the most important concerning aspects of making power with the A340E transmission. That is, pushing big power through the shifts. The stock transmission ECU will reduce the throttle position a good bit. But I've gone a step further and reduced timing and ignition during the shift as well, to help further drop the power during the gear change. I'm pretty pleased with the results. I'll gladly admit that I had help with this, and if anyone is interested in implementing something like this, I'm happy to give details as to what worked for me.

I still struggle with fuel delivery utilizing my stock fuel feed system. I have an Aeromotive 340LPH pump. I was thinking the pump wasn't getting enough power to meet it's potential. But after doing a direct wire modification from the battery through a relay, to the pump, I see no noticeable improvement in flow as registered by the AFR gauge and the fuel pressure sensor in the rail. This makes me think it may be either the feed line itself, or the damper - I know these are known to be restrictive on the Supras, perhaps they are on our cars as well. Either way, I'm not going to nickel and dime it any further (I needed to do the power modification anyway), so I'll just budget for a dual-pump and fresh fuel line setup sometime next year.

I did find a few minutes to clean up some plumbing that I hastily hooked up as my fabricator/tuner and I were fabricating the intercooler piping.

One of my most useful changes over the past month or so was the stock stereo tape player input hack. https://www.clublexus.com/forums/gs-...-aux-port.html I spent $15 on a little bluetooth device that transmits the audio from my phone into this input. Sounds quite good! Far superior to the FM-transmitter hack. If you have the original audio, and are able to solder, this is a worthwhile 2 hour time investment.

I'll finish with as close to a beauty shot as this 20 year old can muster. I found a set of wheels priced well and close enough to not pass up. Being the geek that I am, I can tell you that these 18X10 wheels with 265/35 and 285/35 tires weigh 3 and 6 lbs heavier than the stock wheels with the 215 series all-seasons. Not bad, IMO. And they look okay too, although certainly not as fancy as some.

Happy Holidays, all

The following users liked this post:

firelizard (04-02-21)

#140

Happy one year Covid-versary, everyone. Given the nature of these times and the nature of myself, I've of course been kept busy with a few projects over the past few months. A couple I have completed and a couple of others I'm getting close on and will share them in the coming weeks.

Added a crashbar. It was custom built for the car, no I don't have the skill to build these things myself. Not as sturdy as the factory bar, but it's sturdier than the absent factory bar which had been absent since about 2016 when I installed the FMIC. Grade 8 bolts and used some 6mm aluminum spacers to push it a bit further forward than the fabricator had designed in order to clear and maximize space to the intercooler. Had to wait a few days for snow to clear and temps to get up to freezing before I could get it outside and do some minor hacking with my angle grinder to make room for the 1+ gallon windshield washer reservoir these cars are fitted with.

I've been working toward a front brake upgrade for a while. More to come on that at a later date. But to this end, I needed to install some RCA's on the front ball-joint connection in order to make space between the new calipers and the steering arm that attaches to the knuckle. The dilemma in this RCA spacer is that it would lower my front suspension by over a half inch. The front was already sitting lower than the rear. This would only make the problem worse.

I'm very pleased with the Bilstein struts and drop springs I have installed. The ride is perfect for me and I didn't want to abandon hundreds of dollars worth of quality suspension to spend hundreds (or thousands) on quality coilovers to make room for upgraded front calipers. After many hours of research, measurements, and calls to different suspension shops, I found that coilover sleeves are a thing and they fit the diameter of these struts quite nicely. These sleeves are really designed for the standard 2.5" diameter "race springs" found in coilover setups. Most of the coil spring on our cars (stock or aftermarket) are greater than this 2.5" diameter, but for the coil at the very bottom where it rests on the seat of the strut. But it was VERY close. So I did some grinding on the inner radius of the bottom coil of my two front Vogtland springs that removed enough material that the sleeves could pass through.

I mounted them up and put a few miles on the car. Overall, I was very happy.

I then installed 17mm RCAs, and took the opportunity to paint the springs and adjust the perch accordingly on the sleeve. It's a little tricky determining the correct amount of change for the spring seat to account for a specific ride height - and far less convenient than a true coilover - but still, more reasonable than the alternatives to me.

Overall I'm very pleased. The adjustments that I made to the ride height were slight. Which means I didn't have to apply much preload to the spring - something I had angst and concern over - as I didn't want to find the car was more prone to bottoming or floaty in the front. I've honestly found no adverse effects thus far, and been able to maintain proper ride height in the front to align with the rear.

Added a crashbar. It was custom built for the car, no I don't have the skill to build these things myself. Not as sturdy as the factory bar, but it's sturdier than the absent factory bar which had been absent since about 2016 when I installed the FMIC. Grade 8 bolts and used some 6mm aluminum spacers to push it a bit further forward than the fabricator had designed in order to clear and maximize space to the intercooler. Had to wait a few days for snow to clear and temps to get up to freezing before I could get it outside and do some minor hacking with my angle grinder to make room for the 1+ gallon windshield washer reservoir these cars are fitted with.

I've been working toward a front brake upgrade for a while. More to come on that at a later date. But to this end, I needed to install some RCA's on the front ball-joint connection in order to make space between the new calipers and the steering arm that attaches to the knuckle. The dilemma in this RCA spacer is that it would lower my front suspension by over a half inch. The front was already sitting lower than the rear. This would only make the problem worse.

I'm very pleased with the Bilstein struts and drop springs I have installed. The ride is perfect for me and I didn't want to abandon hundreds of dollars worth of quality suspension to spend hundreds (or thousands) on quality coilovers to make room for upgraded front calipers. After many hours of research, measurements, and calls to different suspension shops, I found that coilover sleeves are a thing and they fit the diameter of these struts quite nicely. These sleeves are really designed for the standard 2.5" diameter "race springs" found in coilover setups. Most of the coil spring on our cars (stock or aftermarket) are greater than this 2.5" diameter, but for the coil at the very bottom where it rests on the seat of the strut. But it was VERY close. So I did some grinding on the inner radius of the bottom coil of my two front Vogtland springs that removed enough material that the sleeves could pass through.

I mounted them up and put a few miles on the car. Overall, I was very happy.

I then installed 17mm RCAs, and took the opportunity to paint the springs and adjust the perch accordingly on the sleeve. It's a little tricky determining the correct amount of change for the spring seat to account for a specific ride height - and far less convenient than a true coilover - but still, more reasonable than the alternatives to me.

Overall I'm very pleased. The adjustments that I made to the ride height were slight. Which means I didn't have to apply much preload to the spring - something I had angst and concern over - as I didn't want to find the car was more prone to bottoming or floaty in the front. I've honestly found no adverse effects thus far, and been able to maintain proper ride height in the front to align with the rear.

#141

Good work man, you're keeping busy. Car's looking great! Getting close to a complete project?

The following users liked this post:

KyleH (03-31-21)

#142

A little update regarding fuel. For a while I've been battling limited fuel pressure at the rail as I add boost. This went from strapping a go-pro under the hood to monitor fuel pressure on a gauge, to a proper fuel pressure sensor, to multiple rebuilds of the stock Aristo hanger setup (including a fresh filter), warrantied & different 340lph brand fuel pumps, and hours of research and analysis on my datalogs. I came to the conclusion that the 340LPH fuel pump just wasn't enough for my needs.

I have been running a flex fuel setup since I installed the single turbo. However, even on pump gas, I was finding that above 12-14 psi the pressure on the rail was not rising with boost pressure, and the AFRs were going toward lean shortly thereafter. On e85, the issue was only compounded.

So after doing some reading and researching, I decided to go ahead and modify the stock GS hanger I had stored away 4+ years ago to handle a TI F90000295 pump. It's also known as the "Walboro 525" or "Hellcat" pump. This one in fact flows a bit more than the standard, as it lacks a check-valve that would otherwise reduce flow. Radiumauto test flowed this pump to 485LPH at 45psi. By comparison, the old pump I was running would be having the best day of it's life to flow 340lph at 40psi. So with that difference in flow, I thought why not spend a couple of weeks building a hanger and seeing how far this new pump could get me.

While I was at it, I wanted to get rid of the stock damper and fuel filter, along with the stock fuel lines, as I felt these were certainly not helping me any. So I picked up some e-85 compliant push-lock fuel hose, along with a high flowing Radiumauto fuel filter, and all the necessary hose ends to connect from the 8an outlet in the bulkhead to the 8an connection at the back of my fuel rail.

I expected that in due time, I would indeed be moving to a nicer hanger with a dual pump setup. But I rationalized this effort based on the small amount of money it would take to hack up and modify the stock GS300 hanger to fit this larger pump.

I got it all together and the results were good, but not as great as I'd hoped. I'd hoped I'd be able to get my boost pressure up north of 20psi on E85 with adequate fuel pressure to go along with it.

My findings are that on pump gas, I'm able to keep a rising fuel pressure (1:1) as boost goes up to the 17-18psi limit I have. But on e85 (flex fuel sensor reports about e65) my fuel pressure levels off with boost at around 11-12 psi. It maintains about 50-51psi in the fuel rail as boost continues to rise, but the AFRs suffer as a result. Definitely surprised I'm not able to get more out of the system. I checked voltage with the pump running, and I was only seeing 12.1 volts at the pump plug. It's 14.0 volts when it's not running. I have some ideas on how to boost that up to 13+ with some wiring changes at the pump hanger, as this is where some smaller gauge wire is located, likely adding resistance. But I'm resigned to the fact that even if I do get an extra volt or even two, it's not going to be enough to get me 20+ psi on e85 that I'd like. I am very surprised how much more pump it's taking to flow the amount of e85 that this engine wants. Or maybe just surprised the pump isn't putting out as much as I expected. My 1000cc injectors are at about 70% duty cycle as I'm running out of pump.

At this point, it looks like I'm going to go ahead and invest in the triple hanger solution. I haven't decided if I'll re-use the new 90000295 fuel pump or not. Since it doesn't have a check valve, it would need to be my primary pump running all the time. Which I suppose would be okay, but I'll look to consult some technical experts before I do that to make sure it does make sense. The good news is that aside from running an additional heavy gauge wire and relay from the battery, this should be a pretty straight-forward plug & play operation to drop in the new hanger.

I have been running a flex fuel setup since I installed the single turbo. However, even on pump gas, I was finding that above 12-14 psi the pressure on the rail was not rising with boost pressure, and the AFRs were going toward lean shortly thereafter. On e85, the issue was only compounded.

So after doing some reading and researching, I decided to go ahead and modify the stock GS hanger I had stored away 4+ years ago to handle a TI F90000295 pump. It's also known as the "Walboro 525" or "Hellcat" pump. This one in fact flows a bit more than the standard, as it lacks a check-valve that would otherwise reduce flow. Radiumauto test flowed this pump to 485LPH at 45psi. By comparison, the old pump I was running would be having the best day of it's life to flow 340lph at 40psi. So with that difference in flow, I thought why not spend a couple of weeks building a hanger and seeing how far this new pump could get me.

While I was at it, I wanted to get rid of the stock damper and fuel filter, along with the stock fuel lines, as I felt these were certainly not helping me any. So I picked up some e-85 compliant push-lock fuel hose, along with a high flowing Radiumauto fuel filter, and all the necessary hose ends to connect from the 8an outlet in the bulkhead to the 8an connection at the back of my fuel rail.

I expected that in due time, I would indeed be moving to a nicer hanger with a dual pump setup. But I rationalized this effort based on the small amount of money it would take to hack up and modify the stock GS300 hanger to fit this larger pump.

I got it all together and the results were good, but not as great as I'd hoped. I'd hoped I'd be able to get my boost pressure up north of 20psi on E85 with adequate fuel pressure to go along with it.

My findings are that on pump gas, I'm able to keep a rising fuel pressure (1:1) as boost goes up to the 17-18psi limit I have. But on e85 (flex fuel sensor reports about e65) my fuel pressure levels off with boost at around 11-12 psi. It maintains about 50-51psi in the fuel rail as boost continues to rise, but the AFRs suffer as a result. Definitely surprised I'm not able to get more out of the system. I checked voltage with the pump running, and I was only seeing 12.1 volts at the pump plug. It's 14.0 volts when it's not running. I have some ideas on how to boost that up to 13+ with some wiring changes at the pump hanger, as this is where some smaller gauge wire is located, likely adding resistance. But I'm resigned to the fact that even if I do get an extra volt or even two, it's not going to be enough to get me 20+ psi on e85 that I'd like. I am very surprised how much more pump it's taking to flow the amount of e85 that this engine wants. Or maybe just surprised the pump isn't putting out as much as I expected. My 1000cc injectors are at about 70% duty cycle as I'm running out of pump.

At this point, it looks like I'm going to go ahead and invest in the triple hanger solution. I haven't decided if I'll re-use the new 90000295 fuel pump or not. Since it doesn't have a check valve, it would need to be my primary pump running all the time. Which I suppose would be okay, but I'll look to consult some technical experts before I do that to make sure it does make sense. The good news is that aside from running an additional heavy gauge wire and relay from the battery, this should be a pretty straight-forward plug & play operation to drop in the new hanger.

#143

Intermediate

Just wondering.. Seems like a lot to do for a few psi boost. I may be naive here but Fuel Pressure Regulator or the sense libe may meed some looking at.

Best of luck

Best of luck

#144

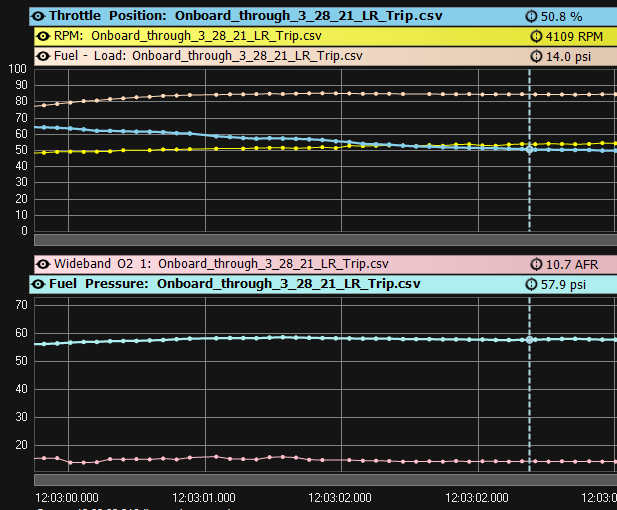

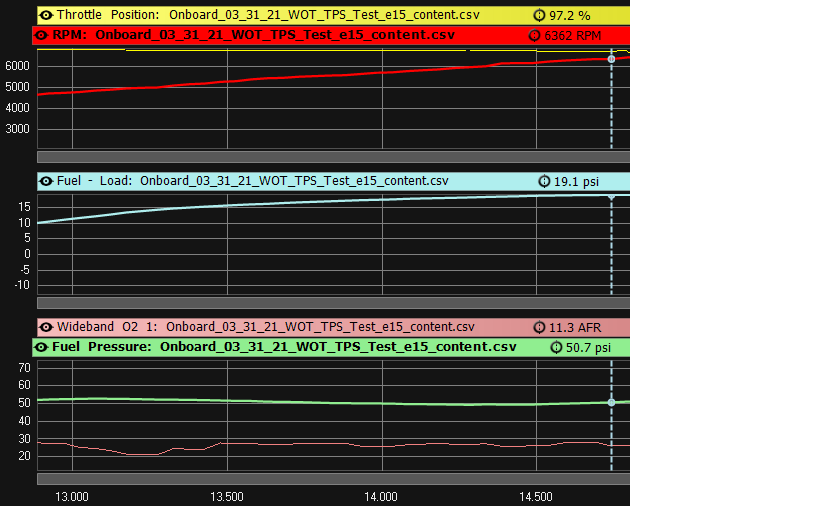

The reality is that when I'm in conditions where the car isn't demanding as much fuel, the pressure is rising fine / normally with boost. Example - 50% throttle at 4100 RPM with 14psi - fuel pressure at the rail is at 58psi. But at 100% throttle, 6400RPM with 19psi, fuel pressure at the rail is down to 50psi.

Partial throttle, lower RPM - fuel pressure is strong.

Full throttle, higher RPM, high boost, fuel pressure is not keeping pace with boost pressure.

Now I'm not claiming victory yet. I'm just saying that I've turned over every stone and looked around every corner possible to try and still coming up shorter than I'd hoped on the single pump. Open to other ideas, as I'm out of my own at this point, other than to say I'm just out of pump.

#145

I'm playing the fuel delivery game too as you probably know. May end up going with the PHR triple hanger too. But I'm going to have it dynoed on the one 525 and see how it does. Tired of spending money on the car (like that will ever end lol). If it makes good numbers, great! If not, more pump!

There is one possible factor I wanted to mention. Where exactly did you get your pump from? I'm sure we all know by now about the massive amount of knock off's of these pumps out there. I have received some over the years and you have to be able to tell the signs. That being said. These do work, but not well. And it throws people for a loop trying to figure out what's wrong. You must buy these pumps and things like NGK spark plugs from licensed authorized dealers only now days. These two brands are the highest fraudulent produced parts on the planet. You can not get these things on Amazon or eBay anymore. That are all fake. Do some research. So I hope you got it somewhere legit, because if not, you may be totally fine on a single pump if its actually a real TI/Walbro. Just throwing that out there and hope it might help if you did get it somewhere (cheap). And for others reading to take care to watch out for as well.

There is one possible factor I wanted to mention. Where exactly did you get your pump from? I'm sure we all know by now about the massive amount of knock off's of these pumps out there. I have received some over the years and you have to be able to tell the signs. That being said. These do work, but not well. And it throws people for a loop trying to figure out what's wrong. You must buy these pumps and things like NGK spark plugs from licensed authorized dealers only now days. These two brands are the highest fraudulent produced parts on the planet. You can not get these things on Amazon or eBay anymore. That are all fake. Do some research. So I hope you got it somewhere legit, because if not, you may be totally fine on a single pump if its actually a real TI/Walbro. Just throwing that out there and hope it might help if you did get it somewhere (cheap). And for others reading to take care to watch out for as well.

#147

I'm playing the fuel delivery game too as you probably know. May end up going with the PHR triple hanger too. But I'm going to have it dynoed on the one 525 and see how it does. Tired of spending money on the car (like that will ever end lol). If it makes good numbers, great! If not, more pump!

There is one possible factor I wanted to mention. Where exactly did you get your pump from? I'm sure we all know by now about the massive amount of knock off's of these pumps out there. I have received some over the years and you have to be able to tell the signs. That being said. These do work, but not well. And it throws people for a loop trying to figure out what's wrong. You must buy these pumps and things like NGK spark plugs from licensed authorized dealers only now days. These two brands are the highest fraudulent produced parts on the planet. You can not get these things on Amazon or eBay anymore. That are all fake. Do some research. So I hope you got it somewhere legit, because if not, you may be totally fine on a single pump if its actually a real TI/Walbro. Just throwing that out there and hope it might help if you did get it somewhere (cheap). And for others reading to take care to watch out for as well.

There is one possible factor I wanted to mention. Where exactly did you get your pump from? I'm sure we all know by now about the massive amount of knock off's of these pumps out there. I have received some over the years and you have to be able to tell the signs. That being said. These do work, but not well. And it throws people for a loop trying to figure out what's wrong. You must buy these pumps and things like NGK spark plugs from licensed authorized dealers only now days. These two brands are the highest fraudulent produced parts on the planet. You can not get these things on Amazon or eBay anymore. That are all fake. Do some research. So I hope you got it somewhere legit, because if not, you may be totally fine on a single pump if its actually a real TI/Walbro. Just throwing that out there and hope it might help if you did get it somewhere (cheap). And for others reading to take care to watch out for as well.

I did pick this pump up off of Amazon. I saw the MFR = Ti Automotive and didn't notice it wasn't being sold by them at time of purchase. It was sold by a third party. I sent them a note through Amazon and we'll see how it goes. With that said I didn't pay $75 for this pump, and am familiar / would expect the $65 pumps on ebay are surely junk. Sadly, expected a little more oversight from Amazon to police these issues. I intend to do a bench test with the pump to see what the output looks like. I spoke to a representative at Ti Automotive today to see about how I can spot a knock-off. He didn't have any tips that helped me. Everything in my kit looked very authentic, down to a little Ti Automotive card. He said he could identify pretty easily with the connector as well. I'm assuming all the proper stamping was on the pump body - but again I'll have to look closer when I remove the pump in the coming days. He also felt it VERY unlikely that the pump was faulty (if it's a legitimate pump) or otherwise unable to keep up with my needs at the ~500+ hp mark.

#149

Well I finally went ahead and bit the bullet and went with a legitimate twin pump solution. The single pump, despite that fact it was an imperfect home-hacked solution made out of a stock hanger, just wasn't enough. I documented the majority of the process and put it on my channel:

There aren't many options out there. I went with the Powerhouse Racing unit. This hanger is a pretty comprehensive solution, including a jet pump valve, connection point for your sending unit, quality machining and wiring, and of course the ability to carry 3 pumps all into the stock location.

#whatsinthebox

#whatsinthebox

The barrels -2 feeds and 1 return. I plugged one of the feeds. I'm feeding with a single 8an line and a 6an return.

For pumps, I ordered the TI Automotive F90000274 AKA Walboro 485 at the same time along with the hanger. This is to compliment my larger F90000295 AKA Walboro 525 in the hanger.

Pumps assembled and ready to go (sans sock filters)

Stock sending unit attached and ready:

Going down into the tank. I had to cut the end off of the little finger (it actually acts as a stop for the float when the tank is full) that you can see hanging out and over the lip of the tank. It wasn't advertised that you needed to do this, but I just didn't have the clearance. Maybe it would have bent, but maybe the entire arm would have broken. I felt this was a reasonable compromise.

Here it is all the way in and buttoned up. The little screws they send seem just a tad shorter than I'd have liked, but they worked. I ended up routing the power wires counter-clockwise instead of clockwise as they are seen in the picture.

Wiring complete. Each pump has it's own dedicated relay circuit. Each circuit has a 25 amp fuse. I utilized Radium Engineering for the relays along with many other parts of my fuel system. I've been very pleased with their products thus far. The secondary pump is activated by my Haltech switching the black/ground relay wire to ground based on RPM & boost. Both relays are energized with the constant power from the factory fuel pump positive lead. The primary pump & relay is permanently grounded - so as before, when key is on, primary pump is active. I made an error initially as I had a lapse in judgement and connected the Haltech to the blue/positive relay side. I quickly found the error in my ways and made the change.

Overall the installation went well. I am very pleased with the product and outcome. I ran into a few minor issues:

1) The pump brackets were installed backward - easy enough to pull the bolt and rotate 180 degrees.

2) Missing eyelets for the ground wires - again - easy enough, had these on hand

3) Modification of the aluminum cover that goes over the hanger - easy enough, just a little hammering

4) Connection hoses weren't proper length - had to cut / shorten them to fit

None of the above things are deal-breakers, but their documentation could have been better in the instances of number 3 & 4 which were known. Items 1 & 2 are just quality control issues.

So far results have been only positive. I've put maybe 100 miles on the car since installation. During that time I've been doing datalogging and tuning. The fuel pressure issue at the fuel rail during higher boost levels is completely gone. I am now seeing a 1:1 rising rate of steady fuel pressure when I'm in boost, even at ~20psi.

So here are some turbo noises post installation:

There aren't many options out there. I went with the Powerhouse Racing unit. This hanger is a pretty comprehensive solution, including a jet pump valve, connection point for your sending unit, quality machining and wiring, and of course the ability to carry 3 pumps all into the stock location.

#whatsinthebox

#whatsintheboxThe barrels -2 feeds and 1 return. I plugged one of the feeds. I'm feeding with a single 8an line and a 6an return.

For pumps, I ordered the TI Automotive F90000274 AKA Walboro 485 at the same time along with the hanger. This is to compliment my larger F90000295 AKA Walboro 525 in the hanger.

Pumps assembled and ready to go (sans sock filters)

Stock sending unit attached and ready:

Going down into the tank. I had to cut the end off of the little finger (it actually acts as a stop for the float when the tank is full) that you can see hanging out and over the lip of the tank. It wasn't advertised that you needed to do this, but I just didn't have the clearance. Maybe it would have bent, but maybe the entire arm would have broken. I felt this was a reasonable compromise.

Here it is all the way in and buttoned up. The little screws they send seem just a tad shorter than I'd have liked, but they worked. I ended up routing the power wires counter-clockwise instead of clockwise as they are seen in the picture.

Wiring complete. Each pump has it's own dedicated relay circuit. Each circuit has a 25 amp fuse. I utilized Radium Engineering for the relays along with many other parts of my fuel system. I've been very pleased with their products thus far. The secondary pump is activated by my Haltech switching the black/ground relay wire to ground based on RPM & boost. Both relays are energized with the constant power from the factory fuel pump positive lead. The primary pump & relay is permanently grounded - so as before, when key is on, primary pump is active. I made an error initially as I had a lapse in judgement and connected the Haltech to the blue/positive relay side. I quickly found the error in my ways and made the change.

Overall the installation went well. I am very pleased with the product and outcome. I ran into a few minor issues:

1) The pump brackets were installed backward - easy enough to pull the bolt and rotate 180 degrees.

2) Missing eyelets for the ground wires - again - easy enough, had these on hand

3) Modification of the aluminum cover that goes over the hanger - easy enough, just a little hammering

4) Connection hoses weren't proper length - had to cut / shorten them to fit

None of the above things are deal-breakers, but their documentation could have been better in the instances of number 3 & 4 which were known. Items 1 & 2 are just quality control issues.

So far results have been only positive. I've put maybe 100 miles on the car since installation. During that time I've been doing datalogging and tuning. The fuel pressure issue at the fuel rail during higher boost levels is completely gone. I am now seeing a 1:1 rising rate of steady fuel pressure when I'm in boost, even at ~20psi.

So here are some turbo noises post installation:

The following 2 users liked this post by KyleH:

firelizard (04-22-21),

TrueGS300 (11-30-21)

#150

Pole Position

Well I finally went ahead and bit the bullet and went with a legitimate twin pump solution. The single pump, despite that fact it was an imperfect home-hacked solution made out of a stock hanger, just wasn't enough. I documented the majority of the process and put it on my channel: https://youtu.be/h9MPYpnrkpY

There aren't many options out there. I went with the Powerhouse Racing unit. This hanger is a pretty comprehensive solution, including a jet pump valve, connection point for your sending unit, quality machining and wiring, and of course the ability to carry 3 pumps all into the stock location.

#whatsinthebox

#whatsinthebox

The barrels -2 feeds and 1 return. I plugged one of the feeds. I'm feeding with a single 8an line and a 6an return.

For pumps, I ordered the TI Automotive F90000274 AKA Walboro 485 at the same time along with the hanger. This is to compliment my larger F90000295 AKA Walboro 525 in the hanger.

Pumps assembled and ready to go (sans sock filters)

Stock sending unit attached and ready:

Going down into the tank. I had to cut the end off of the little finger (it actually acts as a stop for the float when the tank is full) that you can see hanging out and over the lip of the tank. It wasn't advertised that you needed to do this, but I just didn't have the clearance. Maybe it would have bent, but maybe the entire arm would have broken. I felt this was a reasonable compromise.

Here it is all the way in and buttoned up. The little screws they send seem just a tad shorter than I'd have liked, but they worked. I ended up routing the power wires counter-clockwise instead of clockwise as they are seen in the picture.

Wiring complete. Each pump has it's own dedicated relay circuit. Each circuit has a 25 amp fuse. I utilized Radium Engineering for the relays along with many other parts of my fuel system. I've been very pleased with their products thus far. The secondary pump is activated by my Haltech switching the black/ground relay wire to ground based on RPM & boost. Both relays are energized with the constant power from the factory fuel pump positive lead. The primary pump & relay is permanently grounded - so as before, when key is on, primary pump is active. I made an error initially as I had a lapse in judgement and connected the Haltech to the blue/positive relay side. I quickly found the error in my ways and made the change.

Overall the installation went well. I am very pleased with the product and outcome. I ran into a few minor issues:

1) The pump brackets were installed backward - easy enough to pull the bolt and rotate 180 degrees.

2) Missing eyelets for the ground wires - again - easy enough, had these on hand

3) Modification of the aluminum cover that goes over the hanger - easy enough, just a little hammering

4) Connection hoses weren't proper length - had to cut / shorten them to fit

None of the above things are deal-breakers, but their documentation could have been better in the instances of number 3 & 4 which were known. Items 1 & 2 are just quality control issues.

So far results have been only positive. I've put maybe 100 miles on the car since installation. During that time I've been doing datalogging and tuning. The fuel pressure issue at the fuel rail during higher boost levels is completely gone. I am now seeing a 1:1 rising rate of steady fuel pressure when I'm in boost, even at ~20psi.

So here are some turbo noises post installation: https://youtu.be/ScxejH_sNgE

There aren't many options out there. I went with the Powerhouse Racing unit. This hanger is a pretty comprehensive solution, including a jet pump valve, connection point for your sending unit, quality machining and wiring, and of course the ability to carry 3 pumps all into the stock location.

#whatsinthebox

#whatsintheboxThe barrels -2 feeds and 1 return. I plugged one of the feeds. I'm feeding with a single 8an line and a 6an return.

For pumps, I ordered the TI Automotive F90000274 AKA Walboro 485 at the same time along with the hanger. This is to compliment my larger F90000295 AKA Walboro 525 in the hanger.

Pumps assembled and ready to go (sans sock filters)

Stock sending unit attached and ready:

Going down into the tank. I had to cut the end off of the little finger (it actually acts as a stop for the float when the tank is full) that you can see hanging out and over the lip of the tank. It wasn't advertised that you needed to do this, but I just didn't have the clearance. Maybe it would have bent, but maybe the entire arm would have broken. I felt this was a reasonable compromise.

Here it is all the way in and buttoned up. The little screws they send seem just a tad shorter than I'd have liked, but they worked. I ended up routing the power wires counter-clockwise instead of clockwise as they are seen in the picture.

Wiring complete. Each pump has it's own dedicated relay circuit. Each circuit has a 25 amp fuse. I utilized Radium Engineering for the relays along with many other parts of my fuel system. I've been very pleased with their products thus far. The secondary pump is activated by my Haltech switching the black/ground relay wire to ground based on RPM & boost. Both relays are energized with the constant power from the factory fuel pump positive lead. The primary pump & relay is permanently grounded - so as before, when key is on, primary pump is active. I made an error initially as I had a lapse in judgement and connected the Haltech to the blue/positive relay side. I quickly found the error in my ways and made the change.

Overall the installation went well. I am very pleased with the product and outcome. I ran into a few minor issues:

1) The pump brackets were installed backward - easy enough to pull the bolt and rotate 180 degrees.

2) Missing eyelets for the ground wires - again - easy enough, had these on hand

3) Modification of the aluminum cover that goes over the hanger - easy enough, just a little hammering

4) Connection hoses weren't proper length - had to cut / shorten them to fit

None of the above things are deal-breakers, but their documentation could have been better in the instances of number 3 & 4 which were known. Items 1 & 2 are just quality control issues.

So far results have been only positive. I've put maybe 100 miles on the car since installation. During that time I've been doing datalogging and tuning. The fuel pressure issue at the fuel rail during higher boost levels is completely gone. I am now seeing a 1:1 rising rate of steady fuel pressure when I'm in boost, even at ~20psi.

So here are some turbo noises post installation: https://youtu.be/ScxejH_sNgE

OMG, awesome. Issue fixed and you can hear the turbo sing!!