1UZ VVTI O-ring

#31

Rookie

Thread Starter

OP here.

Almost 3 years after the repair and the M2x77 Viton O-ring is working fine. The sizing and amount of clamping force (around 29% of cross-section) seemed appropriate. Much more and the edge of the timing tube would deform slightly between bolt locations. This size was above the standard minimum of 25% squeeze and showed no deformation of the bolted joint.

There is obviously much more to proper seal selection in any application. Temperature, material, groove size, etc. The only engineered seal was the factory quad seal from Toyota which is unavailable by itself. This was merely my best judgement on what was available to pick from.

The only issue I could foresee longterm is O-ring quality. It works for now, so the seal is adequate. How long will the elastomer keep its clamping force on a China sourced O-ring? How long will the material withstand high/low temperatures? Who knows. The material quality is almost no doubt inferior to the factory part. But at this point everything is working fine and it was not worth the expense for new Toyota timing tubes at this stage in the vehicle's life.

Here is some information from Parker about one aspect of O-rings.

http://blog.parker.com/o-ring-squeez...-always-better

Almost 3 years after the repair and the M2x77 Viton O-ring is working fine. The sizing and amount of clamping force (around 29% of cross-section) seemed appropriate. Much more and the edge of the timing tube would deform slightly between bolt locations. This size was above the standard minimum of 25% squeeze and showed no deformation of the bolted joint.

There is obviously much more to proper seal selection in any application. Temperature, material, groove size, etc. The only engineered seal was the factory quad seal from Toyota which is unavailable by itself. This was merely my best judgement on what was available to pick from.

The only issue I could foresee longterm is O-ring quality. It works for now, so the seal is adequate. How long will the elastomer keep its clamping force on a China sourced O-ring? How long will the material withstand high/low temperatures? Who knows. The material quality is almost no doubt inferior to the factory part. But at this point everything is working fine and it was not worth the expense for new Toyota timing tubes at this stage in the vehicle's life.

Here is some information from Parker about one aspect of O-rings.

http://blog.parker.com/o-ring-squeez...-always-better

Last edited by gm52594; 12-08-20 at 08:10 AM.

The following users liked this post:

bradland (12-08-20)

#32

Moderator

I continue to sell the o-ring between the metric M2x77 and the SAE 151 with no issue. I've sold thousands at this point, and to this day the only feedback I've gotten was from the OP of this thread.

It's settled definitively in my mind.

mutantcolors on eBay. Again, my rings are not the same as the others. There have been a few Johnny come Lately sellers of these who for the most part have vanished. I've tried them all. Not the same and most often not Viton.

It's settled definitively in my mind.

mutantcolors on eBay. Again, my rings are not the same as the others. There have been a few Johnny come Lately sellers of these who for the most part have vanished. I've tried them all. Not the same and most often not Viton.

OP here.

Almost 3 years after the repair and the M2x77 Viton O-ring is working fine. The sizing and amount of clamping force (around 29% of cross-section) seemed appropriate. Much more and the edge of the timing tube would deform slightly between bolt locations. This size was above the standard minimum of 25% squeeze and showed no deformation of the bolted joint.

There is obviously much more to proper seal selection in any application. Temperature, material, groove size, etc. The only engineered seal was the factory quad seal from Toyota which is unavailable by itself. This was merely my best judgement on what was available to pick from.

The only issue I could foresee longterm is O-ring quality. It works for now, so the seal is adequate. How long will the elastomer keep its clamping force on a China sourced O-ring? How long will the material withstand high/low temperatures? Who knows. The material quality is almost no doubt inferior to the factory part. But at this point everything is working fine and it was not worth the expense for new Toyota timing tubes at this stage in the vehicle's life.

Here is some information from Parker about one aspect of O-rings.

http://blog.parker.com/o-ring-squeez...-always-better

Almost 3 years after the repair and the M2x77 Viton O-ring is working fine. The sizing and amount of clamping force (around 29% of cross-section) seemed appropriate. Much more and the edge of the timing tube would deform slightly between bolt locations. This size was above the standard minimum of 25% squeeze and showed no deformation of the bolted joint.

There is obviously much more to proper seal selection in any application. Temperature, material, groove size, etc. The only engineered seal was the factory quad seal from Toyota which is unavailable by itself. This was merely my best judgement on what was available to pick from.

The only issue I could foresee longterm is O-ring quality. It works for now, so the seal is adequate. How long will the elastomer keep its clamping force on a China sourced O-ring? How long will the material withstand high/low temperatures? Who knows. The material quality is almost no doubt inferior to the factory part. But at this point everything is working fine and it was not worth the expense for new Toyota timing tubes at this stage in the vehicle's life.

Here is some information from Parker about one aspect of O-rings.

http://blog.parker.com/o-ring-squeez...-always-better

mutantcolo, I've saved your listing in my favorites on eBay

#33

Lexus Champion

Hello all,

I have a 1998 LS400 with the 1UZ. I am currently replacing the timing belt, water pump, and all seals. I've read the VVTI pulley O-ring leak is becoming somewhat common so I decided to disassemble and rebuild those with new O-rings while I have everything apart.

Upon disassembly I noticed Lexus used a quad ring instead of an O-ring for this application. I bought two O-rings from eBay that stated they were for 1UZ, 1JZ, 2JZ etc. VVTI cam pulleys. They appear to be number 041 - 3" x 3 1/8" x 1/16" Viton O-rings. They are noticeably smaller than the groove for the quad ring. They take up about half of the groove, maybe a bit more. They DO stand proud from the groove so there is some O-ring contact before the two halves are bolted together but it doesn't feel like a lot to me. Maybe 1/32" of "crush" on the O-ring but this is just a guess.

This size O-ring was mentioned in another post on here that was a write-up of the rebuild. It was a very old post and there was no follow up as to whether it was leaking or ok after some time. Also, in one other post a user claimed that he used this size O-ring and he had a slow seeping leak from the pulleys afterward.

Does anyone have any more information or have done this themselves? I was thinking a number 151 O-ring would be better since it is another 1/32" thicker of an O-ring. Any help on this would be appreciated.

Thanks,

Greg.

I have a 1998 LS400 with the 1UZ. I am currently replacing the timing belt, water pump, and all seals. I've read the VVTI pulley O-ring leak is becoming somewhat common so I decided to disassemble and rebuild those with new O-rings while I have everything apart.

Upon disassembly I noticed Lexus used a quad ring instead of an O-ring for this application. I bought two O-rings from eBay that stated they were for 1UZ, 1JZ, 2JZ etc. VVTI cam pulleys. They appear to be number 041 - 3" x 3 1/8" x 1/16" Viton O-rings. They are noticeably smaller than the groove for the quad ring. They take up about half of the groove, maybe a bit more. They DO stand proud from the groove so there is some O-ring contact before the two halves are bolted together but it doesn't feel like a lot to me. Maybe 1/32" of "crush" on the O-ring but this is just a guess.

This size O-ring was mentioned in another post on here that was a write-up of the rebuild. It was a very old post and there was no follow up as to whether it was leaking or ok after some time. Also, in one other post a user claimed that he used this size O-ring and he had a slow seeping leak from the pulleys afterward.

Does anyone have any more information or have done this themselves? I was thinking a number 151 O-ring would be better since it is another 1/32" thicker of an O-ring. Any help on this would be appreciated.

Thanks,

Greg.

McMaster-Carr offers Viton X profile o-rings:

Dimensions are in inches, but an appropriate cross to metric should work. Round o-ring profile does not fill the square groove in VVTi

#34

Rookie

Thread Starter

The SAE sizing does not work. The 041 size X-ring has a 0.070" cross-section which is too small (20% squeeze) and the next size up, 151, is too large at 0.103" (46% squeeze) when assembled. Either way, the groove diameter is 0.25"... so neither a metric or SAE O-ring, quad ring, or X-ring is going to fill the groove appropriately. The groove is rectangular, not square. If you used a normally available quad or X-ring that filled the diameter of the groove correctly, it would stand MUCH too proud to even be bolted down.

A round O-ring does not fill the groove, but neither do these choices for SAE X-rings. At any rate, the only engineered solution is to purchase a new VVTI pulley. That being said, my use of an M2x77 O-ring has been working for 3 years and I am satisfied with the result.

A round O-ring does not fill the groove, but neither do these choices for SAE X-rings. At any rate, the only engineered solution is to purchase a new VVTI pulley. That being said, my use of an M2x77 O-ring has been working for 3 years and I am satisfied with the result.

Last edited by gm52594; 12-08-20 at 01:18 PM.

#35

Moderator

The SAE sizing does not work. The 041 size X-ring has a 0.070" cross-section which is too small (20% squeeze) and the next size up, 151, is too large at 0.103" (46% squeeze) when assembled. Either way, the square groove diameter is 0.25"... so neither a metric or SAE O-ring, quad ring, or X-ring is going to fill the groove appropriately. The groove is rectangular, not square. If you used a normally available quad or X-ring that filled the diameter of the groove correctly, it would stand MUCH too proud to even be bolted down.

When you say groove diameter are you referring to the width? Unless I'm missing something I get .118" not 0.25"...

The groove has 2 diameters, the inner wall and the outer wall. The distance between the 2 is .118"

Last edited by bradland; 12-08-20 at 01:13 PM.

#36

Rookie

Thread Starter

Yes, the width of the groove is 0.251". Sorry, I should not have said "the square groove diameter". I went back and edited it.

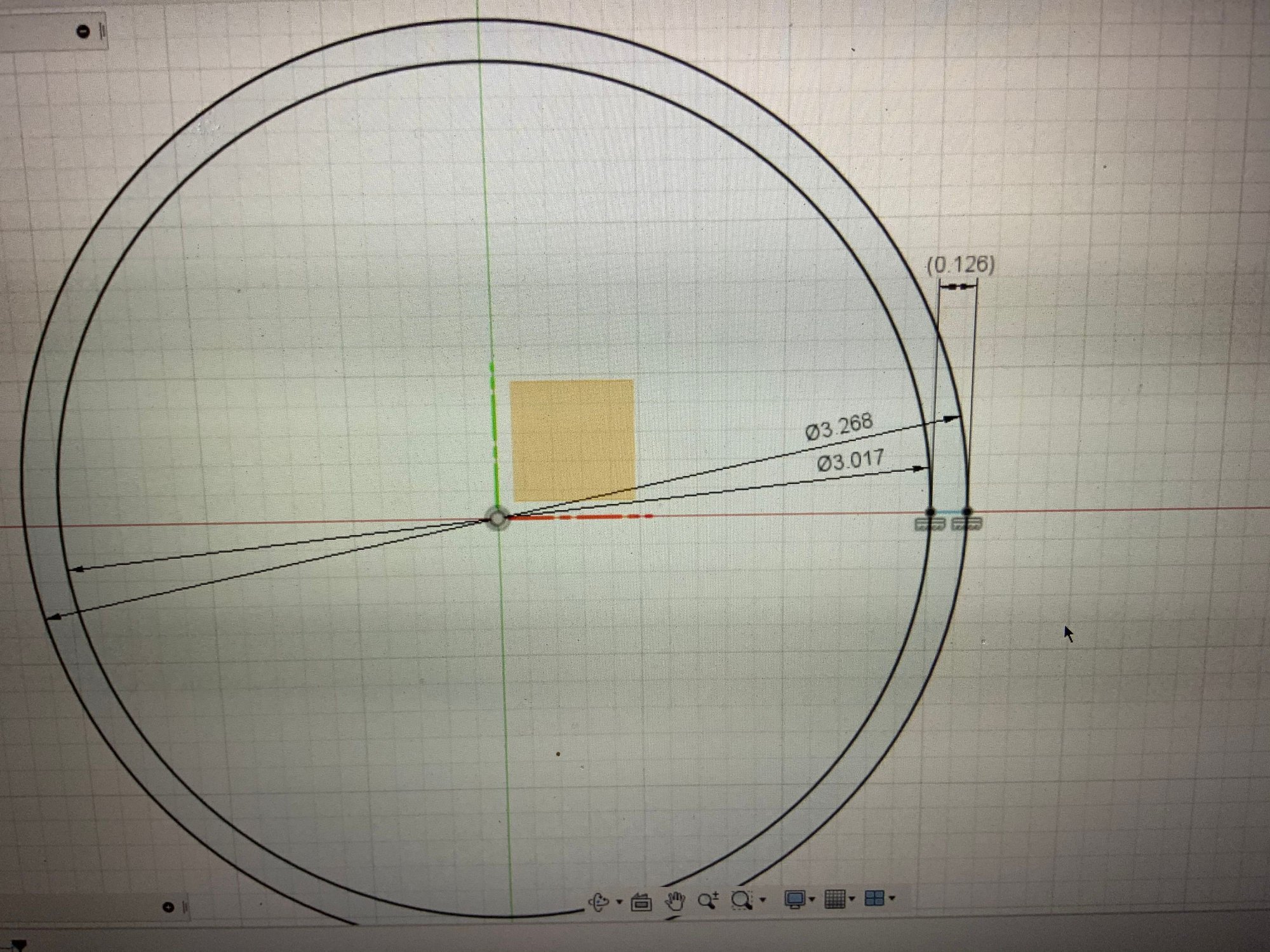

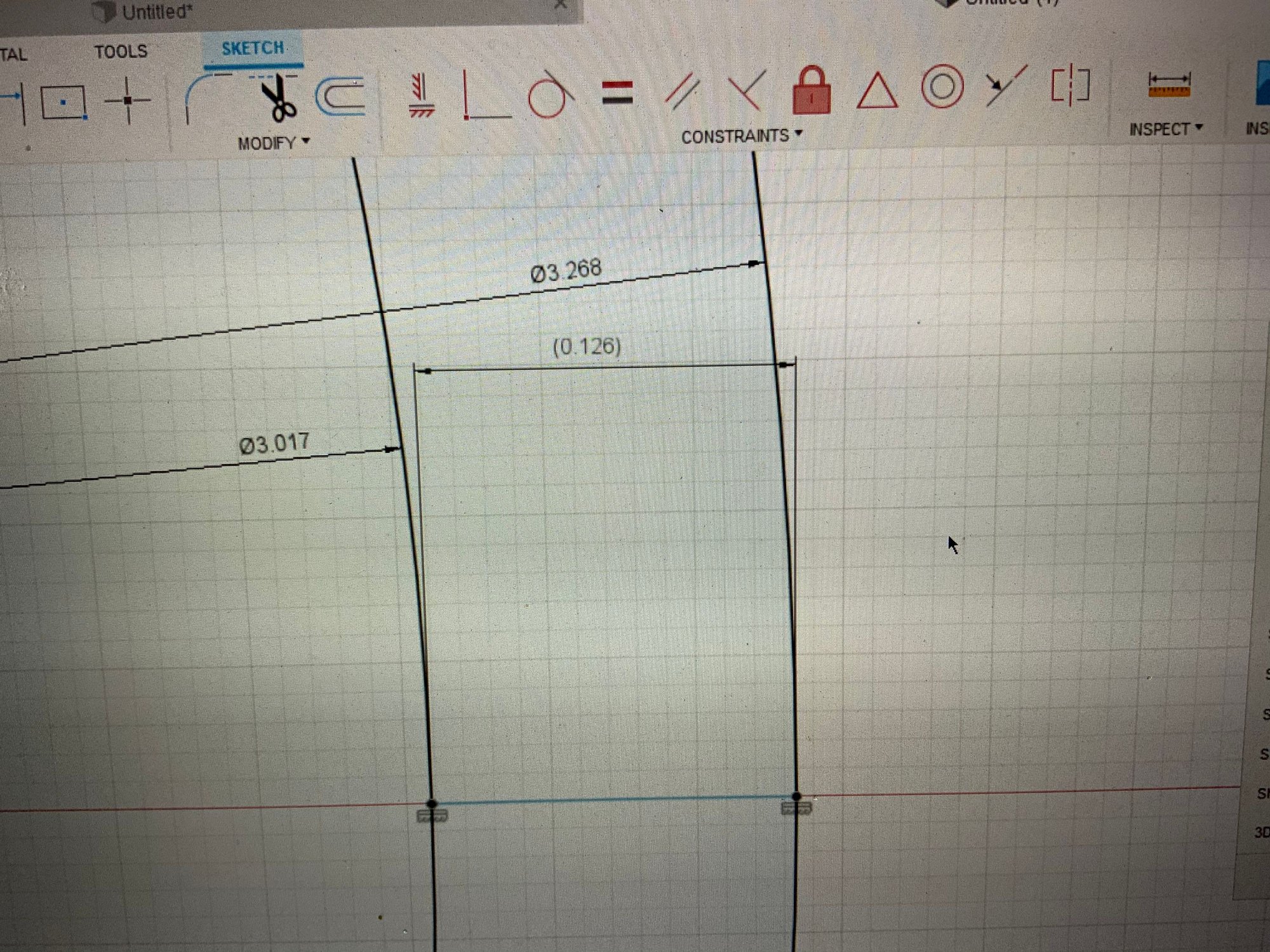

The groove dimensions are 3.017" x 3.268" x .056".

3.017" ID and 3.268" OD for a groove width of 0.251". Unfortunately the groove is not square, it is rectangular. Any conventional metric or SAE O-ring, X-ring, or quad ring is not going to fit this application correctly. So the result is either to use an option with the correct height (squeeze on the O-ring), have one specially manufactured, or purchase a new unit.

The groove dimensions are 3.017" x 3.268" x .056".

3.017" ID and 3.268" OD for a groove width of 0.251". Unfortunately the groove is not square, it is rectangular. Any conventional metric or SAE O-ring, X-ring, or quad ring is not going to fit this application correctly. So the result is either to use an option with the correct height (squeeze on the O-ring), have one specially manufactured, or purchase a new unit.

#37

Moderator

Yes, the width of the groove is 0.251". Sorry, I should not have said "the square groove diameter". I went back and edited it.

The groove dimensions are 3.017" x 3.268" x .056".

3.017" ID and 3.268" OD for a groove width of 0.251". Unfortunately the groove is not square, it is rectangular. Any conventional metric or SAE O-ring, X-ring, or quad ring is not going to fit this application correctly. So the result is either to use an option with the correct height (squeeze on the O-ring), have one specially manufactured, or purchase a new unit.

The groove dimensions are 3.017" x 3.268" x .056".

3.017" ID and 3.268" OD for a groove width of 0.251". Unfortunately the groove is not square, it is rectangular. Any conventional metric or SAE O-ring, X-ring, or quad ring is not going to fit this application correctly. So the result is either to use an option with the correct height (squeeze on the O-ring), have one specially manufactured, or purchase a new unit.

#40

Rookie

Thread Starter

Ok, that's figuring in the total of both sides. Yes, you're right, 0.126" diameter. I apologize.

An M2x77 quad ring would be more suitable if you could find it, but I could not find one already made. I tried an M2.5X77 O-ring, but that has a cross-section of 0.098" and that was too much squeeze on the O-ring. When assembling, it caused some deformity in the bolted joint.

I could also not find any metric quad or X-rings readily available. I'm still not so sure the factory ring wasn't a rectangular profile... since the diameter is 0.126" and the depth is only 0.056". If you had a reasonable squeeze (30ish percent) with a 0.080" cross-section ring, you still have 0.046" of gap in the groove.

An M2x77 quad ring would be more suitable if you could find it, but I could not find one already made. I tried an M2.5X77 O-ring, but that has a cross-section of 0.098" and that was too much squeeze on the O-ring. When assembling, it caused some deformity in the bolted joint.

I could also not find any metric quad or X-rings readily available. I'm still not so sure the factory ring wasn't a rectangular profile... since the diameter is 0.126" and the depth is only 0.056". If you had a reasonable squeeze (30ish percent) with a 0.080" cross-section ring, you still have 0.046" of gap in the groove.

Last edited by gm52594; 12-08-20 at 02:01 PM.

#41

Lexus Champion

Yes, the width of the groove is 0.251". Sorry, I should not have said "the square groove diameter". I went back and edited it.

The groove dimensions are 3.017" x 3.268" x .056".

3.017" ID and 3.268" OD for a groove width of 0.251". Unfortunately the groove is not square, it is rectangular. Any conventional metric or SAE O-ring, X-ring, or quad ring is not going to fit this application correctly. So the result is either to use an option with the correct height (squeeze on the O-ring), have one specially manufactured, or purchase a new unit.

The groove dimensions are 3.017" x 3.268" x .056".

3.017" ID and 3.268" OD for a groove width of 0.251". Unfortunately the groove is not square, it is rectangular. Any conventional metric or SAE O-ring, X-ring, or quad ring is not going to fit this application correctly. So the result is either to use an option with the correct height (squeeze on the O-ring), have one specially manufactured, or purchase a new unit.

About 3 years ago, I installed these round o-rings on 1998 LS400 VVTi with no leaks to date...

A slightly larger X-profile o-ring could be compressed to work?

It's going to be trial and error here.

I went through a similar excercise replacing fuse box cover gasket with bulk x-profile buna- N rubber cord stock

https://www.clublexus.com/forums/ls-...er-gasket.html

#42

Moderator

I'm starting to see YouTubers replace the O-ring inside the VVTi without removing the timing tube assembly from the cam.

Doing this eliminates the need to remove the cam or even the timing belt. Maybe I've been napping under the LS tree for so long other (GS, IS, etc.) owners have been doing this for a while..?

If this is a viable option, I can't see why it's not, this becomes a simple preventative maintenance job.

Any thoughts?

One example-

Doing this eliminates the need to remove the cam or even the timing belt. Maybe I've been napping under the LS tree for so long other (GS, IS, etc.) owners have been doing this for a while..?

If this is a viable option, I can't see why it's not, this becomes a simple preventative maintenance job.

Any thoughts?

One example-

The following users liked this post:

BNastee (02-05-24)

#43

Rookie

Thread Starter

Yes, you could do a 1UZ timing tube O-ring in the vehicle without removing the camshafts if that was your only concern.

Keep in mind, the timing belt has to be removed on a 1UZ though, it's not the same process as a 2JZ. The reason for also removing the camshafts was to replace the cam seals - they are captured and can't be replaced without removing the entire camshaft. With this amount of time and mileage on them, usually they are toast. Also, the cam seals are a huge diameter which means the rotational speed on the lip seal is very high.

So if removing a timing belt to service the timing tube O-ring, the cam seals are probably suspect as well. It's a good opportunity to replace the timing belt, cam seals, crank seal, timing tube O-ring, valve cover gaskets, spark plug grommets, etc. All these rubber parts are generally part of a good timing belt replacement procedure.

Keep in mind, the timing belt has to be removed on a 1UZ though, it's not the same process as a 2JZ. The reason for also removing the camshafts was to replace the cam seals - they are captured and can't be replaced without removing the entire camshaft. With this amount of time and mileage on them, usually they are toast. Also, the cam seals are a huge diameter which means the rotational speed on the lip seal is very high.

So if removing a timing belt to service the timing tube O-ring, the cam seals are probably suspect as well. It's a good opportunity to replace the timing belt, cam seals, crank seal, timing tube O-ring, valve cover gaskets, spark plug grommets, etc. All these rubber parts are generally part of a good timing belt replacement procedure.

The following users liked this post:

BNastee (02-05-24)

Thread

Thread Starter

Forum

Replies

Last Post

Forrestb

GS - 2nd Gen (1998-2005)

8

04-22-16 06:56 AM