Improved LED Reverse Lamps?

#1

Pole Position

Thread Starter

Still reviewing LED reverse lamps offering meaningful improvement over OEM 7440 incandescent bulbs.

Improved luminouis intensity is of interest, but equivalent light output with significantly lower power consumption would be acceptable.

Best LED bulb design offers 90% less power consumption to equivalent Incandescent lumen output

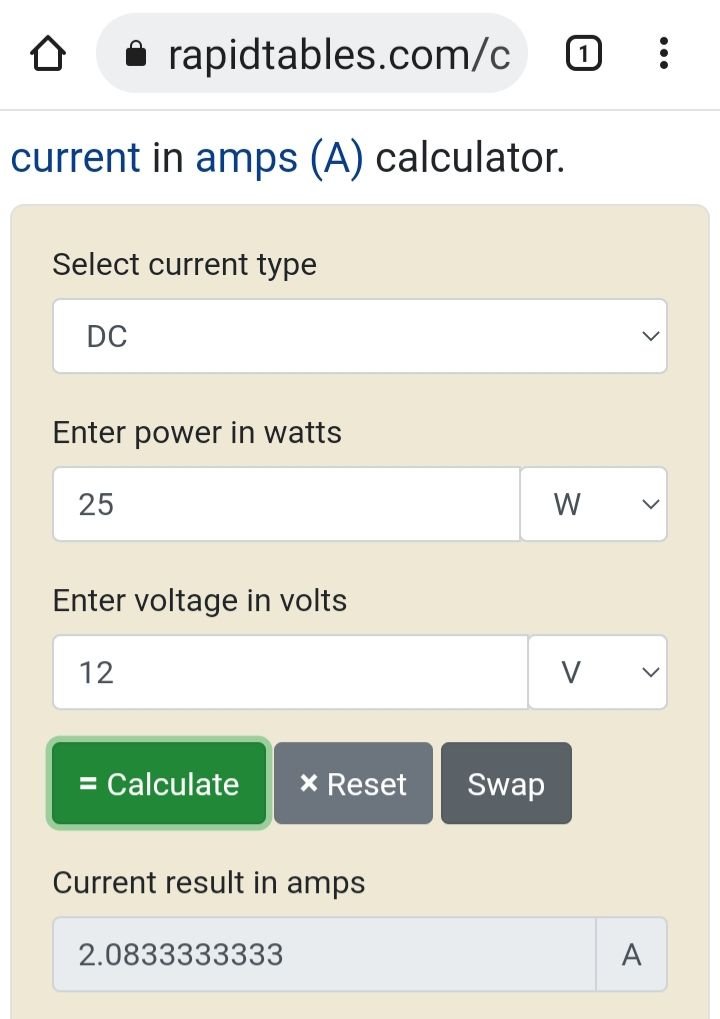

Our reverse lamps are switched via the selector switch on transmission, sliding/wiping contacts are not optimally designed for a 50 watt (4.16 amp) incandescent load...

Thanks

Improved luminouis intensity is of interest, but equivalent light output with significantly lower power consumption would be acceptable.

Best LED bulb design offers 90% less power consumption to equivalent Incandescent lumen output

Our reverse lamps are switched via the selector switch on transmission, sliding/wiping contacts are not optimally designed for a 50 watt (4.16 amp) incandescent load...

Thanks

Last edited by YODAONE; 09-28-21 at 08:44 PM.

#2

Lexus Fanatic

I have the above you won't be disappointed by the light output they are getting close to a headlight bulb. Specs say they draw 1.7 amps I tested them and got 1.1 an incandescent bulb draws about 2 amps. They are absolutely not to be used where the bulb is always on they get way too hot and won't last. Excellent for backup lights.

They are 2.5" long so make sure you have the clearance.

#3

Pole Position

Thread Starter

https://www.amazon.com/dp/B07GBTQQKY

I have the above you won't be disappointed by the light output they are getting close to a headlight bulb. Specs say they draw 1.7 amps I tested them and got 1.1 an incandescent bulb draws about 2 amps. They are absolutely not to be used where the bulb is always on they get way too hot and won't last. Excellent for backup lights.

They are 2.5" long so make sure you have the clearance.

I have the above you won't be disappointed by the light output they are getting close to a headlight bulb. Specs say they draw 1.7 amps I tested them and got 1.1 an incandescent bulb draws about 2 amps. They are absolutely not to be used where the bulb is always on they get way too hot and won't last. Excellent for backup lights.

They are 2.5" long so make sure you have the clearance.

Watts to Amps conversion..

Lex2k: Do you require a reverse tail lamp lense assembly and socket so you can advise fitment?

#4

Lexus Fanatic

#6

Pole Position

Thread Starter

Optimally, an LED bulb converts 90% of power consumed to light output and 10% heat, while the inverse for incandescent bulbs.

I have sold discrete LED's at an OEM design engineering level.

I have interfaced with an engineering/manufacturer of Marine grade LED interior lamps.

I have interfaced with an engineer/manufacturer of industrial LED bulbs.

They advise engineered LED bulbs are 90% efficient (energy to light production).

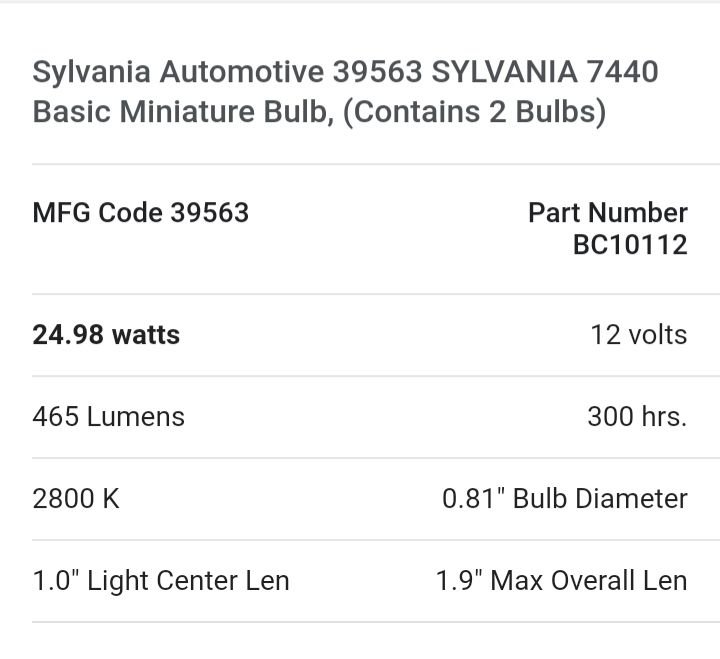

Sylvania rates their 7440 incandescent bulb at about 500 (465) Lumens (light output) at 25 (24.98) watts (power consumption).

So a 7440 25 watt incandescent bulb at 500 lumens, in LED equavalent (lumens).should consume about 2.5 watts.

In extrapolation:

A 5W LED bulb would produce 1000 lumens.

A 10W LED bulb would produce 2000 lumens, subject to heat dissipation...

I have sold discrete LED's at an OEM design engineering level.

I have interfaced with an engineering/manufacturer of Marine grade LED interior lamps.

I have interfaced with an engineer/manufacturer of industrial LED bulbs.

They advise engineered LED bulbs are 90% efficient (energy to light production).

Sylvania rates their 7440 incandescent bulb at about 500 (465) Lumens (light output) at 25 (24.98) watts (power consumption).

So a 7440 25 watt incandescent bulb at 500 lumens, in LED equavalent (lumens).should consume about 2.5 watts.

In extrapolation:

A 5W LED bulb would produce 1000 lumens.

A 10W LED bulb would produce 2000 lumens, subject to heat dissipation...

Last edited by YODAONE; 09-28-21 at 08:45 PM.

#7

Moderator

Optimally, an LED bulb converts 90% of power consumed to light output and 10% heat, while the inverse for incandescent bulbs.

I have sold discrete LED's at an OEM design engineering level.

I have interfaced with an engineering/manufacturer of Marine grade LED interior lamps.

I have interfaced with an engineer/manufacturer of industrial LED bulbs.

They advise engineered LED bulbs are 90% efficient (energy to light production).

Sylvania rates their 7440 incandescent bulb at about 500 (465) Lumens (light output) at 25 (24.98) watts (power consumption).

So a 7440 25 watt incandescent bulb at 500 lumens, in LED equavalent (lumens).should consume about 2.5 watts.

In extrapolation:

A 5W LED bulb would produce 1000 lumens.

A 10W LED bulb would produce 2000 lumens, subject to heat dissipation...

I have sold discrete LED's at an OEM design engineering level.

I have interfaced with an engineering/manufacturer of Marine grade LED interior lamps.

I have interfaced with an engineer/manufacturer of industrial LED bulbs.

They advise engineered LED bulbs are 90% efficient (energy to light production).

Sylvania rates their 7440 incandescent bulb at about 500 (465) Lumens (light output) at 25 (24.98) watts (power consumption).

So a 7440 25 watt incandescent bulb at 500 lumens, in LED equavalent (lumens).should consume about 2.5 watts.

In extrapolation:

A 5W LED bulb would produce 1000 lumens.

A 10W LED bulb would produce 2000 lumens, subject to heat dissipation...

I used to be told that there's the performance barrier 20% but in 2018, 20.7% was announced. ie 40 W tungsten incandescent bulb 1.86%. So the ratio is more than 10.

You will know more here. https://en.wikipedia.org/wiki/Light-...#cite_note-187

Trending Topics

#8

Pole Position

Thread Starter

Are you sure that an LED bulb converts 90% of power consumed to light output and 10% heat?

I used to be told that there's the performance barrier 20% but in 2018, 20.7% was announced. ie 40 W tungsten incandescent bulb 1.86%. So the ratio is more than 10.

You will know more here. https://en.wikipedia.org/wiki/Light-...#cite_note-187

I used to be told that there's the performance barrier 20% but in 2018, 20.7% was announced. ie 40 W tungsten incandescent bulb 1.86%. So the ratio is more than 10.

You will know more here. https://en.wikipedia.org/wiki/Light-...#cite_note-187

So my engineering contact claimed 90% efficiency on his bulbs; not using an AC - DC power supply or cooling fan.

I actually interviewed with him on Chicago television a decade or so ago about his technology...

If the norm is 20% then extrapolate from that

At higher lumen output,.thermal management becomes increasingly difficult.

Despite efficiency of LED's,headlamp bulbs require fans to dissipate heat.

Efficiency varies based on application.

An article on topic suggesting that running more current for increased light output reduces efficiency.

:

Identifying the Causes of LED Efficiency Droop

By Steven KeepingContributed By Electronic Products

2011-10-18

LEDs operate most efficiently at low currents (of just tens of milliamps). As the current increases, efficiency tails off in a phenomenon known as “efficiency droop.” For practical reasons, the LED lighting industry uses drive currents that are much higher than those for which efficiency is optimum. LED manufacturers are keen to address this compromise, but scientists are finding it tough to pin down the cause of the loss of efficiency.

This article takes a look at the effect of efficiency droop on LED performance and describes two popular theories on its origin.

Trading efficiency for light output

For fairly arbitrary reasons, the high-brightness LED industry has settled on a forward current of 350 mA as something of a de facto standard for its products. The reason for this choice primarily revolves around it being the drive current at which a 1 mm² chip typically dissipates 1 W (the actual dissipation is normally closer to 1.25 W).

In the early days of high-brightness LEDs, a forward current of 280 mA was more typical, and today many chips run at higher forward currents than 350 mA. However, neither 280 mA, 350 mA, nor higher currents are anywhere near the most efficient forward current with which to power a high-brightness LED. As efficiency (usually quoted as lumens/watt or lm/W) is something that gets the industry excited, this seems surprising.

A high-brightness LED reaches its peak efficiency at a few tens of milliamps and thereafter, it’s all downhill. Figure 1 illustrates the relationship between efficiency and forward current (ILED) for a single LED (plus a pair and triplet of devices connected in series). For the single device (in this case a Maxim chip), the efficiency peaks at 70 percent at 75 mA, slowly declining to 59 percent at 350 mA.

Figure 1: LED efficiency slowly declines as forward current is increased. (Courtesy: Maxim.)So why doesn’t the high-brightness LED sector recommend that chips operate at their most efficient point? The reason is that although they run well, LEDs just do not produce enough light at low forward current. The wick has to be turned up much higher to produce a useful output: 350 mA is a good compromise between light output, efficiency, and longevity (increasing the drive current above this level risks raising the junction temperature such that LED lifetime is compromised).

LED manufacturers are working hard to understand the underlying causes of efficiency droop so that they can improve performance at the preferred operating point. While physical limitations will probably prevent efficiency droop being eliminated altogether, if the rate of decline when past the peak can be decreased the problem would be partially mitigated.

Unfortunately, it is proving difficult to determine exactly what’s going on.

Causes of efficiency droop

An early suspicion among scientists investigating the problem was that increased temperature plays a role in efficiency droop. Certainly, elevated junction temperature for LEDs is not a good thing, because it shortens the devices’ lifetime.

As it turns out, heat is not the culprit. Figure 2 shows the measured external quantum efficiency (EQE) and light output power at different heat sink temperatures as a function of forward current. It can be seen that he EQE at all currents decreases as the temperature rises, and the efficiency droop phenomenon is present at all temperatures. However, the peak efficiency decreases more rapidly at lower temperatures as the current increases (i.e., the slope of the efficiency graph is steeper).

This implies that the magnitude of the droop actually decreases with increasing temperature. The outcome has led scientists to conclude that while an increasing temperature patently decreases the overall efficiency, temperature does not increase–and thus, is not the root cause of–efficiency droop.

Figure 2: External quantum efficiency of GaInN multiple quantum well LED at heat sink temperatures of 25° to 150°C vs current.

We need to look beyond temperature for the source of the problem.

Unfortunately, although temperature has been eliminated, there is no definitive alternative. However, there are two promising theories: Electron leakage and Auger recombination.

Because LED efficiency sits firmly in the realm of quantum physics, the theories aren’t that easy to understand. For example, one recent academic paper¹ states that polarization fields that occur at higher drive currents in the multiple quantum well active region and the electron blockage layer of the LED enhance the leakage of injected electrons into the p-type GaN layer, causing the efficiency droop. In simpler terms, that means physical effects associated with higher currents push electrons out of the recombination zone so they never have the chance to meet with holes and release photons.

In a related theory, others claim the source of efficiency droop involves excess tunneling current reducing carrier injection efficiency.² In other words, many electrons don’t make it to the recombination zone in the first place.

An alternative approach claims the key to understanding efficiency droop is a process called direct Auger recombination. This usually involves electrons and holes recombining and instead of emitting a photon, the energy is transferred to a third carrier. Since the process involves three carriers, the problem would tend to get worse at the high carrier densities common to higher currents lowering efficiency. But calculations reveal this phenomenon can’t account for all of observed efficiency droop.

However, another group of researchers now claims that a combination of direct and indirect Auger recombination does make the sums add up. The process is again complex, and involves electron–phonon coupling and alloy scattering (or Coulomb scattering) by charged defects (phonons are the quantum description of the LED’s crystal lattice vibrations).The electron–phonon coupling is particularly strong in nitride semiconductors. Alloy scattering occurs because the crystal structure of InGaN is not uniform.³ Adding the two forms of Auger recombination together approximates to the experimentally observed efficiency reduction.

Minimizing the droop

In the absence of a definitive answer to the cause of efficiency droop, design engineers need to carefully select their LEDs and operating parameters to minimize its effect. In theory this would mean paying particularly close attention to both the devices’ maximum efficiency and the gradient of the efficiency droop curve beyond that point. The shallower the slope, the less the efficiency will drop off as the forward drive current increases. However, in reality this information is difficult to acquire, as manufacturers tend to focus on a single (lm/W) figure at a particular test current rather than providing information across an entire current range.

Cree, for example, has recently released its XLamp MT-G LED (Figure 3) that features its EasyWhite LED for the high-lumen, small-footprint requirements of 35- and 50-W halogen retrofit lamps. The device incorporates an array of LEDs with a total output of 1265 lm and an efficiency of 75 lm/W at 1.1 A shows the product.

Figure 3: Cree’s XLamp MT-G LED.

Seoul Semiconductor offers its Z-Power series LEDs that are said to be suitable light sources for general illumination applications, custom designed solutions, and automotive large LCD backlights. The device delivers 100 lm at a forward current of 350 mA, for an efficiency of about 110 lm/W.

Also, Toshiba’s TL19W01 series of high luminous flux white LEDs offer design engineers another alternative for lighting applications. These devices offer 110 lm at a forward current of 350 mA, for an efficiency of 111 lm/W.

Summary

The LED lighting industry uses drive currents that are much higher than those for which efficiency is optimum, so the phenomenon known as efficiency droop is likely to be with us for some time. While LED scientists continue to try to pin down the cause of this loss of efficiency, by carefully selecting LEDs engineers can minimize its effect. Further information can be obtained by using the provided links to Digi-Key product pages.

References:

- Min-Ho Kim, “Origin of efficiency droop in GaN-based light-emitting diodes,” Applied Physics Letters 91 183507 (2007).

- Bochkareva, N. I. et al., “Defect-related tunneling mechanism of efficiency droop in III-nitride light-emitting diodes,” Applied Physics Letters 96 133502 (2010).

- Emmanouil Kioupakis et al., “Indirect Auger recombination as a cause of efficiency droop in nitride light-emitting diodes,” Applied Physics Letters 98, 161107 (2011).

Last edited by YODAONE; 09-29-21 at 05:53 PM.

#9

Moderator

What is the relationship between an LED and an AC - DC power supply or cooling fan?

#10

Forum Administrator

iTrader: (2)

I also suspect LED technology has improved in 10 years with much broader adoption and use.

#11

Lexus Fanatic

As for output/watt there is a big difference depending on the LED type, manufacture, bulb type and other factors. I personally don't care so much about power/watt in an LED bulb even the worst ones are far better than the original bulbs.

#12

Pole Position

Thread Starter

Several LED headlamps use such cooling to dissipate heat...otherwise a large heat sink.is required...

Since the fan draws power, it detracts from the overall efficiency of an LED lighting system.

See:

https://hikari-led.com/fan-vs-fanles...eadlights.html

Excerpt:

"Many car owners upgrade their factory headlights by swapping halogen bulbs to LED. These bulbs provide brighter lighting, form right beam in both projector and reflector headlights and last much longer, than regular halogen bulbs. The only drawback of the LED bulbs is excessive heat they produce. Hence, such bulbs come equipped with a cooling unit that allows reducing temperature. Modern LED bulbs for high and low beam upgrade feature fan or fanless construction. So, which bulbs are better? Let us consider pros and cons of both constructions, so that you could determine, which ones to consider for your vehicleLeds that come equipped with fan use active cooling. It means that fan rotates and reduces heat. Yet some bulbs with active cooling units are made too big and cannot be normally fitted into the headlight assembly. Yet, there are slim fans that do not require a lot of space in a headlight.

LEDs with passive cooling, or fanless, feature either braided heat sinks, or get cooled by means of internal drivers. Internal driver cooling method is third generation of LED heat elimination. Fanless bulbs feature slimer filament, compared to the LEDs equipped with cooling fan."

Fan-cooled LEDs

As for the "power supply",... LED's illuminate when correct Direct Current (D.C. voltage) is applied.

In the case of a residential A-19 screwin base bulb, it is an Alternating Current (A.C voltage) supply of somewhere between 100 - 230 VAC.

Various electronic components are required to reliably and durably convert AC to DC. Dimmable LED bulbs require additional circuitry yet. Quite possible there are but a few discrete components, but because of its function, right or wrong, I refer to.it as a power supply whereas I refer to a DC - AC converter as an "inverter.".as used on solar panels...a majority of which are 96 -98%. efficient. (These inverters use best quality component to achieve this efficiency , whereas an LED light bulb circuit is very inexpensive)

Perhaps some the AC- DC power conversion efficiency of A-19 household bulbs.

Hope this addresses your questions.

Last edited by YODAONE; 09-29-21 at 09:10 PM.

#13

Pole Position

Thread Starter

I think he's saying the voltage regulator and fan of course add to power draw. Don't think it's significant or matters much. The problem with many LEDs is not so much power draw it's temperature many simply get too hot and don't last as result.

As for output/watt there is a big difference depending on the LED type, manufacture, bulb type and other factors. I personally don't care so much about power/watt in an LED bulb even the worst ones are far better than the original bulbs.

As for output/watt there is a big difference depending on the LED type, manufacture, bulb type and other factors. I personally don't care so much about power/watt in an LED bulb even the worst ones are far better than the original bulbs.

#14

Lexus Fanatic

I did but could not reply your inbox is full.

Thread

Thread Starter

Forum

Replies

Last Post

lastguy

GS - 2nd Gen (1998-2005)

11

10-07-21 10:59 AM