Nitrous and Fuel Line

#1

Been doing research about nitrous on this forum and SF but no luck on good answers to my questions

So for the nitrous gurus out there ...

1) Should the nitrous and fuel line going to the fogger / nozzle from the distribution block be of the same length ?

2) Does the fogger / nozze release the nitrous/fuel combination at the same time inside the runner ? The nitrous being over 900 psi will reach that nozzle first before the fuel being liquid and a lot lower psi. Wouldn't there be a fraction of a second leaning out if the nitrous / fuel do not go out of the nozzle at the same time ?

3) If the fogger / nozzle doesn't control the realease , then is it right to assume that as those solenoids open up , nitrous and fuel races out of that fogger / nozzle. Which means, the shorter lines the better so the combination of nitrous and fuel hits the cylinder faster and you don't waste a lot of it being on the lines ?

Why am I asking ?

Happened to grab an NX Direct port setup almost for nothing so I am contemplating at using it on my build. I know we all get scared of nitrous as causing engine damage. I have said many times that I will not use nitrous but after so much reading and research , I believe now that it is all about how it is setup , tuned and used .

It is a stealth setup being hidden under the runners. But if you observe the length of lines, let's say of nitrous and fuel line going to runner number 1 nozzle from the distribution block (showerhead) , they are not of the same length. The dude says , they use it for 75shots without any problem on his supra.

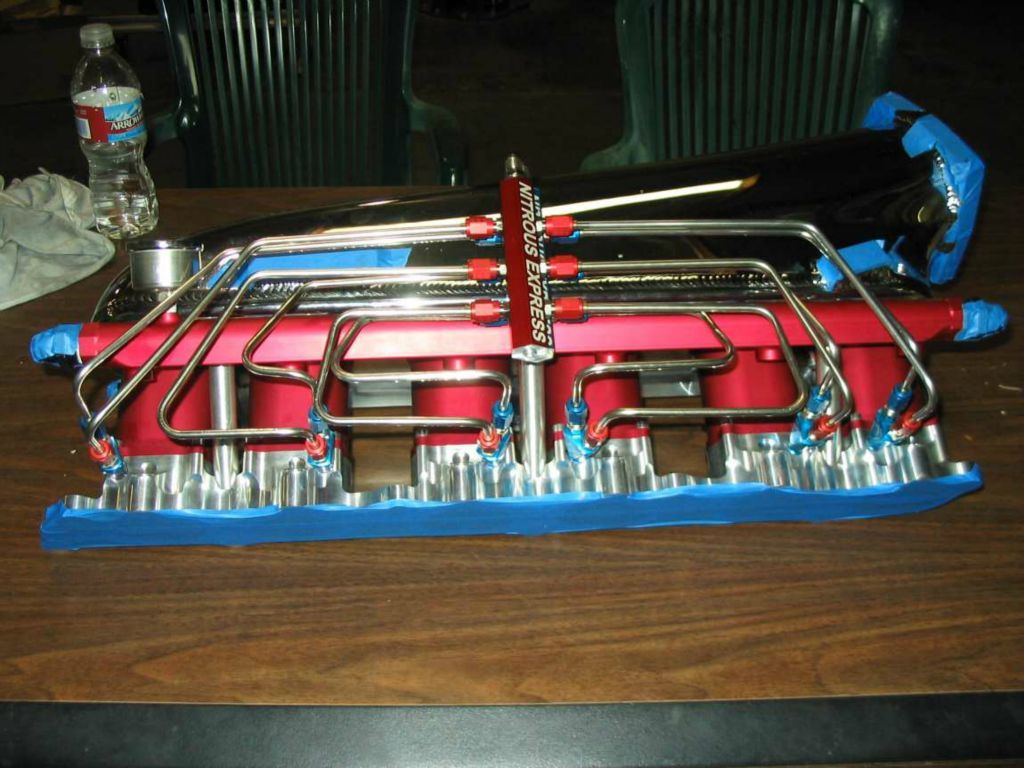

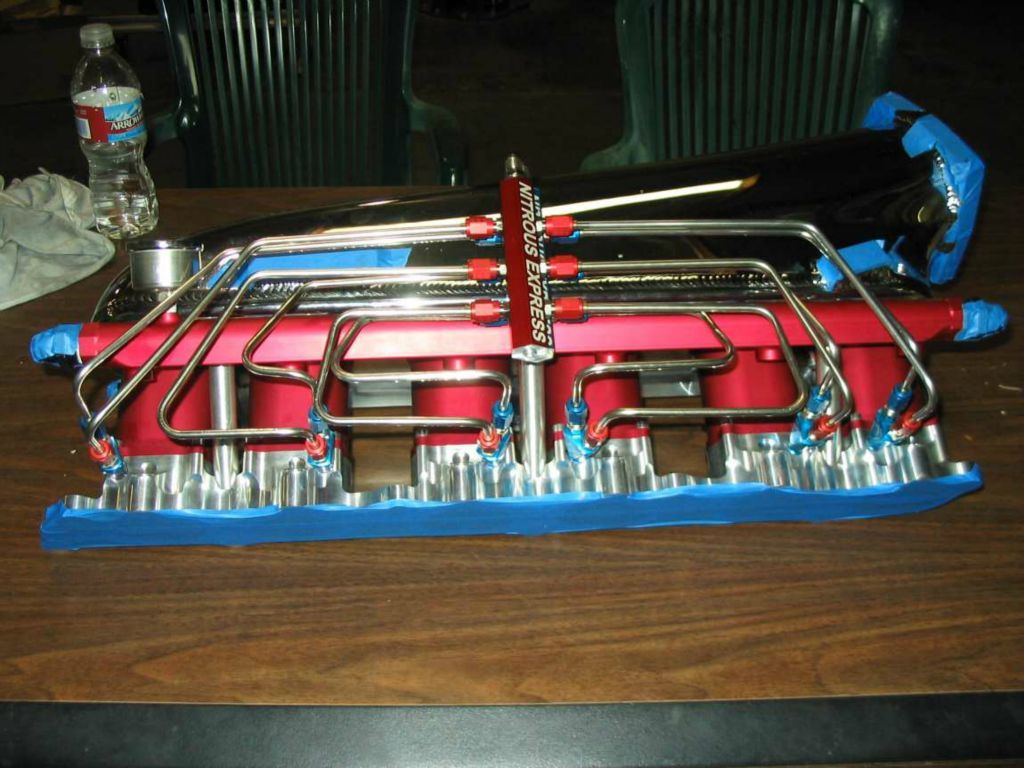

I am planning to redo the plumbing on top of my intake just like the one pictured below. But if I can't plumb it on top of my intake due to the stuff I already have there then I will use it as it is now but I want to make sure those plumbing won't cause me problems of leaning out due to unequal lengths.

So for the nitrous gurus out there ...

1) Should the nitrous and fuel line going to the fogger / nozzle from the distribution block be of the same length ?

2) Does the fogger / nozze release the nitrous/fuel combination at the same time inside the runner ? The nitrous being over 900 psi will reach that nozzle first before the fuel being liquid and a lot lower psi. Wouldn't there be a fraction of a second leaning out if the nitrous / fuel do not go out of the nozzle at the same time ?

3) If the fogger / nozzle doesn't control the realease , then is it right to assume that as those solenoids open up , nitrous and fuel races out of that fogger / nozzle. Which means, the shorter lines the better so the combination of nitrous and fuel hits the cylinder faster and you don't waste a lot of it being on the lines ?

Why am I asking ?

Happened to grab an NX Direct port setup almost for nothing so I am contemplating at using it on my build. I know we all get scared of nitrous as causing engine damage. I have said many times that I will not use nitrous but after so much reading and research , I believe now that it is all about how it is setup , tuned and used .

It is a stealth setup being hidden under the runners. But if you observe the length of lines, let's say of nitrous and fuel line going to runner number 1 nozzle from the distribution block (showerhead) , they are not of the same length. The dude says , they use it for 75shots without any problem on his supra.

I am planning to redo the plumbing on top of my intake just like the one pictured below. But if I can't plumb it on top of my intake due to the stuff I already have there then I will use it as it is now but I want to make sure those plumbing won't cause me problems of leaning out due to unequal lengths.

Last edited by gerrb; 10-01-12 at 11:07 AM.

#2

The nitrous and fuel lines should be of equal length in respect to themselves.

i.e. The nitrous line to cylinder 6 should be the same length from the distribution block as the nitrous line to cylinders 1-5. If the line to 6 is 4 inches, the line to all the others should be as well. The same goes for the fuel lines. They do not need to be equal to one another (fuel and nitrous lines do not need to be equal). However the fuel lines should always be as short as possible and when creating your lines, fuel should take precedence over nitrous in placement and length.

Uneven line lengths will cause some cylinders to receive more nitrous/fuel than others. Causing extended rich and lean conditions in some cylinders. This will have little to ill effects on a small shot like the 75 quoted in the first setup. It will be exacerbated the higher you go and in my opinion it is better to just do it right the first time than to redo it should you wish to go to a much bigger shot later.

Yes, the nitrous will beat the fuel to the nozzles. Yes, when first initiated you will get a lean spike because the nitrous is beating the fuel to the nozzles. Depending mostly on length of the lines and bottle pressure this spike will happen for anywhere from a hundredth of a second to a couple of tenths of a second.

Being that you are running a turbocharged car you are likely running a nice safe rich AF somewhere between 11 and 12.5:1. Thanks to this extra fuel you should be fine with the lean spike depending on the size of the shot you are running. If you wanted to eliminate/minimize the lean spike you are going to need either a progressive controller to start the nitrous at a small amount, which will create a tiny/negligible spike, while the fuel catches up and then go full shot or you'd need to test the length of time the spike occurs in your system via datalogging and wire in a delay for your nitrous solenoid.

There is no need to fear nitrous; like any power adder, when done properly it works beautifully, when done sloppily everything goes boom.

i.e. The nitrous line to cylinder 6 should be the same length from the distribution block as the nitrous line to cylinders 1-5. If the line to 6 is 4 inches, the line to all the others should be as well. The same goes for the fuel lines. They do not need to be equal to one another (fuel and nitrous lines do not need to be equal). However the fuel lines should always be as short as possible and when creating your lines, fuel should take precedence over nitrous in placement and length.

Uneven line lengths will cause some cylinders to receive more nitrous/fuel than others. Causing extended rich and lean conditions in some cylinders. This will have little to ill effects on a small shot like the 75 quoted in the first setup. It will be exacerbated the higher you go and in my opinion it is better to just do it right the first time than to redo it should you wish to go to a much bigger shot later.

Yes, the nitrous will beat the fuel to the nozzles. Yes, when first initiated you will get a lean spike because the nitrous is beating the fuel to the nozzles. Depending mostly on length of the lines and bottle pressure this spike will happen for anywhere from a hundredth of a second to a couple of tenths of a second.

Being that you are running a turbocharged car you are likely running a nice safe rich AF somewhere between 11 and 12.5:1. Thanks to this extra fuel you should be fine with the lean spike depending on the size of the shot you are running. If you wanted to eliminate/minimize the lean spike you are going to need either a progressive controller to start the nitrous at a small amount, which will create a tiny/negligible spike, while the fuel catches up and then go full shot or you'd need to test the length of time the spike occurs in your system via datalogging and wire in a delay for your nitrous solenoid.

There is no need to fear nitrous; like any power adder, when done properly it works beautifully, when done sloppily everything goes boom.

#3

^^^ thank you very much .. well explained and it adds to the knowledge been searching for.

On a perfect setup, I would assume that all nitrous lines from runner 1 to 6 should be the same as you said for balance distribution of nitrous to the cylinders.... but what I am always wondering is on the so many setups I have seen, even from the gallery sections of Nitrous providers , runner 1 to 6 do not have same nitrous line length and it seems to be alright.

e.g. runners on 2jzgte engines

]

]

Well... true, due to so many horror stories about nitrous being blamed as the culprit , many including me had always avoided it till I got this good deal and will use it on my SC. And after a lot of research and reading , just like you said if done right it is a wonderful power adder and nothing to be afraid of.

On a perfect setup, I would assume that all nitrous lines from runner 1 to 6 should be the same as you said for balance distribution of nitrous to the cylinders.... but what I am always wondering is on the so many setups I have seen, even from the gallery sections of Nitrous providers , runner 1 to 6 do not have same nitrous line length and it seems to be alright.

e.g. runners on 2jzgte engines

]

]

Well... true, due to so many horror stories about nitrous being blamed as the culprit , many including me had always avoided it till I got this good deal and will use it on my SC. And after a lot of research and reading , just like you said if done right it is a wonderful power adder and nothing to be afraid of.

#4

Packaging/room constraints. Each of those setups pictured seems to be doing the best that it can in the room it has available. This is most obvious in the first picture you posted. The lines to cylinder 3 and 4 could easily be 80% shorter by just making a 90* turn from the distribution block to the nozzle. Of note is that the distribution blocks are dead head systems (no return lines in a nitrous system) and the shortest lines are the furthest from the inlet of the block (except in pic 3), meaning they are going to get the last and least amount of nitrous/fuel available.

As a product of its immediate nature, nitrous is easy to blame when something goes wrong. Unlike other power adders, if something lets go with nitrous it usually goes the moment the nitrous is introduced. No one blames the turbo when their fuel pump runs out of flow and they detonate their engine to death, but everyone blames the nitrous when the fuel pump never had the flow to keep up with the shot they were running and they detonate their engine to death.

Nitrous is wonderful, horsepower through chemistry.

Keep us posted and provide pics if you decide to redo the lines for that showerhead setup. Also I'd be sure to check those solenoids and all the lines (especially the fuel lines) for debris. Not everyone runs a filter and you just never know what conditions a used system has been put through a single clogged fuel line and you're down for a rebuild on the first shot.

As a product of its immediate nature, nitrous is easy to blame when something goes wrong. Unlike other power adders, if something lets go with nitrous it usually goes the moment the nitrous is introduced. No one blames the turbo when their fuel pump runs out of flow and they detonate their engine to death, but everyone blames the nitrous when the fuel pump never had the flow to keep up with the shot they were running and they detonate their engine to death.

Nitrous is wonderful, horsepower through chemistry.

Keep us posted and provide pics if you decide to redo the lines for that showerhead setup. Also I'd be sure to check those solenoids and all the lines (especially the fuel lines) for debris. Not everyone runs a filter and you just never know what conditions a used system has been put through a single clogged fuel line and you're down for a rebuild on the first shot.

#5

Thanks for the reminders. I will actually run nitrous and fuel to test them for clogs / debris. And I will definitely redo the lines .. in fact I want it on top of the runners / intake ..

I already have found a place for my nitrous and fuel solenoid and have relocated my FPR and IACV.. The pictures below is how they are installed right now and just contemplating the best way to route the lines. In the pictures you still see the showerheads but I am planning to use rectangular distribution boxes. It would have been easy and perfect if I use 18" long SS braided lines for all nitrous and fuel lines. But it would look like a spaghetti mess on top and would be unrully looking. The nearer ports will have extra long lines also but at least you take care of the fact that all ports have equal length from the source of nitrous and fuel. It would have not matter if the lines and nozzle will be under the runners. It just looks a lot better on top.. like a work of art worth showing off.

I already have found a place for my nitrous and fuel solenoid and have relocated my FPR and IACV.. The pictures below is how they are installed right now and just contemplating the best way to route the lines. In the pictures you still see the showerheads but I am planning to use rectangular distribution boxes. It would have been easy and perfect if I use 18" long SS braided lines for all nitrous and fuel lines. But it would look like a spaghetti mess on top and would be unrully looking. The nearer ports will have extra long lines also but at least you take care of the fact that all ports have equal length from the source of nitrous and fuel. It would have not matter if the lines and nozzle will be under the runners. It just looks a lot better on top.. like a work of art worth showing off.

Last edited by gerrb; 10-09-12 at 07:03 PM.

#6

Placement looks good, a nice 90* out of the solenoids and you can have the blocks mounted to the piece of flat you have the solenoids on already. Although that might make for interesting/crowded lines on the innermost sides of the distribution blocks. So probably best to avoid that idea.

The showerheads are cool looking, but as a product of their design any lines coming from them are going to appear like a play dough extrusion. Distribution is nice and even, but uniform aesthetics are lacking. I'd still hold onto them for a later application or a more creative looking setup.

I'll be thinking about routing and will report back.

One idea: Keep the showerheads, turn the solenoids around so that the heads are facing the strut tower instead of the engine, and port the nozzles in on the underside of the manifold. Get your stainless lines and run those from the showerheads, toward the strut tower, underneath the plenum of the manifold and up to the nozzles. This keeps the solenoids and showerheads in full view, the lines aren't a visual mess, all the lines can easily be the same length, and you keep what little room you have around the injectors up top.

The showerheads are cool looking, but as a product of their design any lines coming from them are going to appear like a play dough extrusion. Distribution is nice and even, but uniform aesthetics are lacking. I'd still hold onto them for a later application or a more creative looking setup.

I'll be thinking about routing and will report back.

One idea: Keep the showerheads, turn the solenoids around so that the heads are facing the strut tower instead of the engine, and port the nozzles in on the underside of the manifold. Get your stainless lines and run those from the showerheads, toward the strut tower, underneath the plenum of the manifold and up to the nozzles. This keeps the solenoids and showerheads in full view, the lines aren't a visual mess, all the lines can easily be the same length, and you keep what little room you have around the injectors up top.

Trending Topics

#9

I did something similar with my hard lines as shown above: http://www.supraforums.com/forum/sho...hlight=nitrous

My solution to the nitrous hitting the cylinders first is to bump the fuel map using the standalone when the solenoids come on. The extra fuel from the injectors should easily get there in time with the nitrous.

-scott

My solution to the nitrous hitting the cylinders first is to bump the fuel map using the standalone when the solenoids come on. The extra fuel from the injectors should easily get there in time with the nitrous.

-scott

#10

Motorheaddown - thanks for that thread link. Actually I have gone through it many times cause I like the way how the lines flowed. Simple.. not too crowded. And more likely mine will look very similar to yours. Except I am thinking of not connecting the distribution boxes directly to the solenoids due to space concerns and more likely my distribution boxes will be vertically installed. But yours look cool. I really like it.

SCary400 - thanks for all the insights. I would prefer to keep the lines just on top of the fuel rail and lower runner... as much as possible nothing on top of the plenum. It is kinda crowded there already.

Today - I installed a nitrous gauge , connected my nitrous source from the tank to the front, connected my purge output to the two windshield nozzles. Also decided , just to connect my spray bar source from the same line so I will just use one line from the trunk and one in line nitrous filter.

On the first picture below , the part on top of the rail and lower runner is were I want all those hard lines to go as much as possible.

SCary400 - thanks for all the insights. I would prefer to keep the lines just on top of the fuel rail and lower runner... as much as possible nothing on top of the plenum. It is kinda crowded there already.

Today - I installed a nitrous gauge , connected my nitrous source from the tank to the front, connected my purge output to the two windshield nozzles. Also decided , just to connect my spray bar source from the same line so I will just use one line from the trunk and one in line nitrous filter.

On the first picture below , the part on top of the rail and lower runner is were I want all those hard lines to go as much as possible.

Last edited by gerrb; 10-12-12 at 10:49 AM.

#11

I am posting more of this nitrous setup on my build thread which is on my signature . So if you guys want to follow it .. https://www.clublexus.com/forums/per...pra-mkivs.html ... so I don't have to double post here.

I believe I now have the answers to the questions I posted above after some insights from our good friends here on this forum and after talking to the NX technical support. Thanks to everyone.

Let me summarize for the benefits of the others.

* In a perfect world , if you can get all those lines be of same length , then better . But many times space concerns wouldn't allow us. On every runner , the nitrous and fuel line should more or less be of same length if you can. If not , then the fuel line should at least be shorter. Most especially if the lines are more than 24" long.

* The control of nitrous and fuel flows are all done by the solenoid. The tip of the nozzle just atomize them.The nozzle won't wait for one to arrive and then mix them.. lol... (due to my ignorance , that is what I thought) . If both nitrous and fuel comes out at the same time .. better cause it can be mixed well before they reach the cylinder and no leaning out.

* Shorter lines and the placement of nozzles on the runner dictates the kind of hit you get when you press that nitrous button. You want to soften that hit , make the lines longer. So placement of nozzles on the runner has an effect too.

When it is all said and done , Once you press that button .. you better hang tight on that steering wheel... where ever that car is facing .. it will be like a missile hitting whatever is infront of it... lmaol...

I believe I now have the answers to the questions I posted above after some insights from our good friends here on this forum and after talking to the NX technical support. Thanks to everyone.

Let me summarize for the benefits of the others.

* In a perfect world , if you can get all those lines be of same length , then better . But many times space concerns wouldn't allow us. On every runner , the nitrous and fuel line should more or less be of same length if you can. If not , then the fuel line should at least be shorter. Most especially if the lines are more than 24" long.

* The control of nitrous and fuel flows are all done by the solenoid. The tip of the nozzle just atomize them.The nozzle won't wait for one to arrive and then mix them.. lol... (due to my ignorance , that is what I thought) . If both nitrous and fuel comes out at the same time .. better cause it can be mixed well before they reach the cylinder and no leaning out.

* Shorter lines and the placement of nozzles on the runner dictates the kind of hit you get when you press that nitrous button. You want to soften that hit , make the lines longer. So placement of nozzles on the runner has an effect too.

When it is all said and done , Once you press that button .. you better hang tight on that steering wheel... where ever that car is facing .. it will be like a missile hitting whatever is infront of it... lmaol...

Last edited by gerrb; 10-12-12 at 10:15 AM.

Thread

Thread Starter

Forum

Replies

Last Post

archangels

RX - 1st Gen (1999-2003)

3

04-06-08 10:20 AM