External Shifting R154 is apart - in search of some guidance

#1

Driver

Thread Starter

iTrader: (4)

Join Date: Feb 2012

Location: NC

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

First, I'd like to say thanks in advance and offer a little bit of backstory into what I've got going on here and how arrived to this point. I've got a 93 SC300 with a later model 1JZ/R154 Soarer Swap. The motor runs its *** off, but since day one, I've had this horrendous low RPM noise, a vibration that severely magnified itself in 5th gear and ton of noise from a stop that came and went with clutch engagement. It seemed easy to diagnose - throw out bearing and a couple bearings shot to hell internally. It did not explain my terrifyingly high clutch pedal engagement though - I'm completely out of adjustment up top. I didn't order any parts because I wasn't sure what all I was exactly going to need and I keep hearing of Supra and late Soarer internals not being interchangeable.

So this week, I pulled the motor and transmission out and I find what may be the strangest thing most of us here have seen - I successfully grenaded my pilot bearing, in some pretty awesome fashion - Check out these photos.

I guess that explains a lot of my noise and vibration, especially considering when I cracked the case, everything looked new. There was still writing on the shift forks, white paint on the gears, free spinning bearings, pristine synchros and very very minimal metal on the magnet. I've already decided that since I'm going to be beating the **** out of this transmission, Marlin Crawler upgrades are in store since I'm already this deep into it. I've got both billet forks, the thrust washer, retainer and a couple other minor updates on the way.

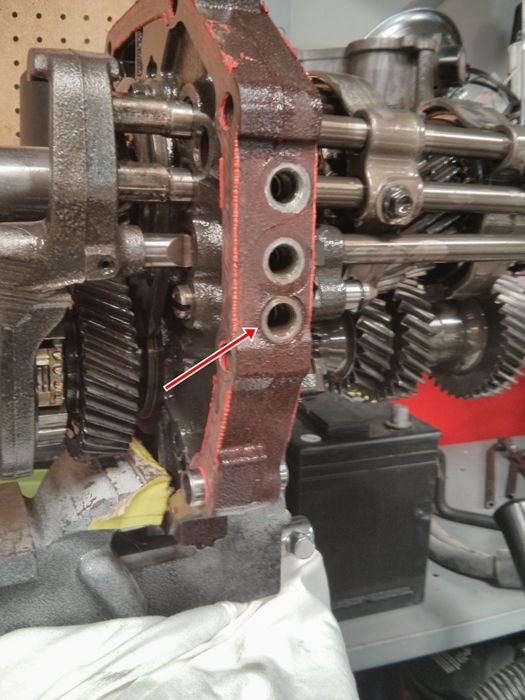

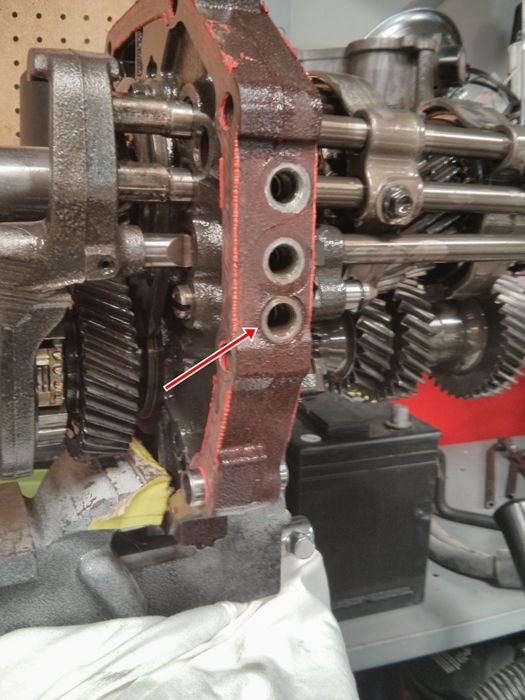

While disassembling, I did find two interesting things I need to ask questions about. Very first and foremost, the most confusing. While removing the springs and ***** from the intermediate plate, the service manual specifically says that there should be 4 of each - One on top, three on the sides. Keeping in mind that this is a Late Soarer unit, the Bottom most bolt did not have a ball or spring behind it - I have shown in this photo which one was missing -

Is this normal for this newer unit? I am confident it did not fall out as I was very meticulous on the removal of the retaining bolt. The transmission was not acting up during shifting either. Always slid right into gear with no fuss or noise.

Second and finally, while tapping out the spring pins, this little guy fell out. I am not sure where it came from - Any tips are appreciated!

For sake of documenting for others, I also noticed a few inconsistencies when using the Service manual intended for an MK3 -

First, According to the manual here that I'm using -

http://www.cygnusx1.net/Supra/Librar...aspx?S=MT&P=51

Step 4 - On the late model trans, I do not have this screw plug on my transmission. It is simply not there.

Second, according to step 14

http://www.cygnusx1.net/Supra/Librar...aspx?S=MT&P=51

I only have one pin, rather than the two demonstrated here.

So this week, I pulled the motor and transmission out and I find what may be the strangest thing most of us here have seen - I successfully grenaded my pilot bearing, in some pretty awesome fashion - Check out these photos.

I guess that explains a lot of my noise and vibration, especially considering when I cracked the case, everything looked new. There was still writing on the shift forks, white paint on the gears, free spinning bearings, pristine synchros and very very minimal metal on the magnet. I've already decided that since I'm going to be beating the **** out of this transmission, Marlin Crawler upgrades are in store since I'm already this deep into it. I've got both billet forks, the thrust washer, retainer and a couple other minor updates on the way.

While disassembling, I did find two interesting things I need to ask questions about. Very first and foremost, the most confusing. While removing the springs and ***** from the intermediate plate, the service manual specifically says that there should be 4 of each - One on top, three on the sides. Keeping in mind that this is a Late Soarer unit, the Bottom most bolt did not have a ball or spring behind it - I have shown in this photo which one was missing -

Is this normal for this newer unit? I am confident it did not fall out as I was very meticulous on the removal of the retaining bolt. The transmission was not acting up during shifting either. Always slid right into gear with no fuss or noise.

Second and finally, while tapping out the spring pins, this little guy fell out. I am not sure where it came from - Any tips are appreciated!

For sake of documenting for others, I also noticed a few inconsistencies when using the Service manual intended for an MK3 -

First, According to the manual here that I'm using -

http://www.cygnusx1.net/Supra/Librar...aspx?S=MT&P=51

Step 4 - On the late model trans, I do not have this screw plug on my transmission. It is simply not there.

Second, according to step 14

http://www.cygnusx1.net/Supra/Librar...aspx?S=MT&P=51

I only have one pin, rather than the two demonstrated here.

#4

Driver

Thread Starter

iTrader: (4)

Join Date: Feb 2012

Location: NC

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

Not a lot of advice going on here, but I will continue to update as I go so that someone else has a reference down the road.

Just ordered all Marlin Crawler parts - shift fork, thrust washer, bearing retainer, driftmotion 3-4 fork, clutch hose and everything I need to seal it back up.

Also, two very important things I have learned with this transmission swap that is absolutely imperative that no one else does - 1) Replace your clutch line with a new line at a minimum or a braided line. Our cars are old cars. Do your self a favor. If you don't suspect your rubber line is ballooning, it is probably deteriorating internally.

2, and this is pivotal. Anyone that has had a transmission out of a car knows how to install a clutch - clutch spline tool, then bolt the pressure plate to it. The TSRM specifically says to slide the pressure plate onto the input shaft, then the clutch, then bolt the transmission in. DO THIS. It sounds ridiculous, and I still cannot mechanically figure out why it is the way it is, but well, it is.

Just ordered all Marlin Crawler parts - shift fork, thrust washer, bearing retainer, driftmotion 3-4 fork, clutch hose and everything I need to seal it back up.

Also, two very important things I have learned with this transmission swap that is absolutely imperative that no one else does - 1) Replace your clutch line with a new line at a minimum or a braided line. Our cars are old cars. Do your self a favor. If you don't suspect your rubber line is ballooning, it is probably deteriorating internally.

2, and this is pivotal. Anyone that has had a transmission out of a car knows how to install a clutch - clutch spline tool, then bolt the pressure plate to it. The TSRM specifically says to slide the pressure plate onto the input shaft, then the clutch, then bolt the transmission in. DO THIS. It sounds ridiculous, and I still cannot mechanically figure out why it is the way it is, but well, it is.

#5

Driver School Candidate

iTrader: (1)

1. Get a magnetic arm everyone sells them and there are cheap it keeps you from making the mistake you already made in tapping on the transmission to remove those springs you don't want to be shaking things up unless you know how it goes back.

2. Put the transmission on a work station big enough to remove and label all your pieces.

3. Since I think this is your first one you should take many before removal pics then remove the part so you have some documentation of your exact transmission for obvious reasons as well as if someone else wanted to use your write as a guide.

2. Put the transmission on a work station big enough to remove and label all your pieces.

3. Since I think this is your first one you should take many before removal pics then remove the part so you have some documentation of your exact transmission for obvious reasons as well as if someone else wanted to use your write as a guide.

#6

Driver

Thread Starter

iTrader: (4)

Join Date: Feb 2012

Location: NC

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

1. Get a magnetic arm everyone sells them and there are cheap it keeps you from making the mistake you already made in tapping on the transmission to remove those springs you don't want to be shaking things up unless you know how it goes back.

2. Put the transmission on a work station big enough to remove and label all your pieces.

3. Since I think this is your first one you should take many before removal pics then remove the part so you have some documentation of your exact transmission for obvious reasons as well as if someone else wanted to use your write as a guide.

2. Put the transmission on a work station big enough to remove and label all your pieces.

3. Since I think this is your first one you should take many before removal pics then remove the part so you have some documentation of your exact transmission for obvious reasons as well as if someone else wanted to use your write as a guide.

Also learned that the Soarer transmission does not have the lower ball and spring - the piece in question goes into the lower hole.

I've got a ton of workspace - probably 2-3 times more than I would ever need - my snap on box and 2 other benches. While I didn't label my parts, They are laid out in order of removal.

#7

Driver

Thread Starter

iTrader: (4)

Join Date: Feb 2012

Location: NC

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

Small update I just learned of. All you guys with a late model soarer trans, the Marlin crawler thrust washer does not fit. Pics coming later. The inside diameter of the mc washer is significantly larger.

Trending Topics

#9

Driver

Thread Starter

iTrader: (4)

Join Date: Feb 2012

Location: NC

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

More info on this -

Here you can see both sides of the washer that came out of my transmission. It is obviously smaller and has an obvious difference in diameter to the MC part. The part that has me thinking is that there is no groove in this washer as there is with the Supra piece. Maybe Toyota wised up and started reinforcing it at the factory? Maybe its a JDM thing, or even 1JZ specific? Regardless, the only thing I replaced was the pin that keeps it home as mine was a little banged up and they are the same size. The MC Bearing retainer plate DOES fit! I'll let the photos do the rest of the talking.

Here you can see both sides of the washer that came out of my transmission. It is obviously smaller and has an obvious difference in diameter to the MC part. The part that has me thinking is that there is no groove in this washer as there is with the Supra piece. Maybe Toyota wised up and started reinforcing it at the factory? Maybe its a JDM thing, or even 1JZ specific? Regardless, the only thing I replaced was the pin that keeps it home as mine was a little banged up and they are the same size. The MC Bearing retainer plate DOES fit! I'll let the photos do the rest of the talking.

#10

Driver

Thread Starter

iTrader: (4)

Join Date: Feb 2012

Location: NC

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

Another small update. The mc bearing retainer and shift fork, as well as the driftmotion fork all work with this trans.

My trans guy that helped me locally seems fairly confident that the thrust washer is no longer a weak point and underwent an upgrade with the trans update. I'll try to keep the thread updated in case I detonate it.

My trans guy that helped me locally seems fairly confident that the thrust washer is no longer a weak point and underwent an upgrade with the trans update. I'll try to keep the thread updated in case I detonate it.

#11

Driver

Thread Starter

iTrader: (4)

Join Date: Feb 2012

Location: NC

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

Many of you may have noticed this same thread going on SupraForums. I'm trying to keep the updates the same, especially here since the info is more valuable to us here and its always good to have it in a couple of places.

Reading over my thread and noticed I forgot to post a piece of vital info for anyone that runs into the same problem with the detent that I did.

this guy -

http://i193.photobucket.com/albums/z...psbb09cd25.jpg

does not drop in from the top or feed through the side of the lower hole. The detents that feed through the top are about the same length, but significantly thicker. Their home is in the intermediate plate, between the shafts. The lower hole on this transmission does not have a ball and spring because the lowest shaft (4th from the top) is fixed - you can see this in my photo with the arrow on it. It is threaded into the plate. This shaft is there only to hold the reverse idler in place and the idler is very different on my trans than most MKIII guys will ever see.

So where does the detent go? While I cleaning the shift shafts before reassembly I noticed they had spots for small detents that sat inside of the shafts themselves, and thats when the light switch clicked on and i figured out how the whole assembly works mechanically. The missing piece installed into one of the shift shafts and its sole purpose is to push the fat ones in the intermediate plate out of the way when the selected gear is engaged so that it forces the other shafts to lock into place - keeping you from engaging more than one gear at a time. If it wasn't there, the shaft would be permanently stuck in the plate.

Thanks again to everyone who helped. The advice given here has been absolutely invaluable. I can't thank Quake enough for his expert tips, tricks and hints!

As a final word, I want to remind everyone one more time - This is for an external shifting Soarer Transmission. Most of what has been discussed in this thread will not work with your MK3 R154.

Reading over my thread and noticed I forgot to post a piece of vital info for anyone that runs into the same problem with the detent that I did.

this guy -

http://i193.photobucket.com/albums/z...psbb09cd25.jpg

does not drop in from the top or feed through the side of the lower hole. The detents that feed through the top are about the same length, but significantly thicker. Their home is in the intermediate plate, between the shafts. The lower hole on this transmission does not have a ball and spring because the lowest shaft (4th from the top) is fixed - you can see this in my photo with the arrow on it. It is threaded into the plate. This shaft is there only to hold the reverse idler in place and the idler is very different on my trans than most MKIII guys will ever see.

So where does the detent go? While I cleaning the shift shafts before reassembly I noticed they had spots for small detents that sat inside of the shafts themselves, and thats when the light switch clicked on and i figured out how the whole assembly works mechanically. The missing piece installed into one of the shift shafts and its sole purpose is to push the fat ones in the intermediate plate out of the way when the selected gear is engaged so that it forces the other shafts to lock into place - keeping you from engaging more than one gear at a time. If it wasn't there, the shaft would be permanently stuck in the plate.

Thanks again to everyone who helped. The advice given here has been absolutely invaluable. I can't thank Quake enough for his expert tips, tricks and hints!

As a final word, I want to remind everyone one more time - This is for an external shifting Soarer Transmission. Most of what has been discussed in this thread will not work with your MK3 R154.

Thread

Thread Starter

Forum

Replies

Last Post

5th, bearing, billet, conversion, external, fell, fork, knocking, noise, r154, sc300, sound, supraforums, transtrans, vibration