IS350 Revision S/C

#62

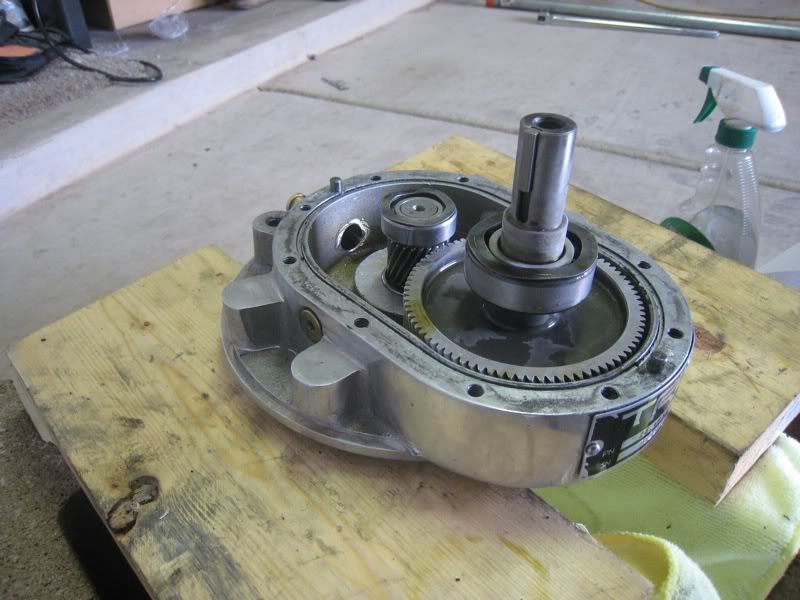

Yes because I rebuilt the C1 with ceramic $$$ bearings on the impeller shaft. The compressor is actually a bit smaller on the C1 vs C2. Needless to say the C1 is in a garbage bag in the corner of my garage after what happened to it a few weeks back. lol

Might as well be glass packed into these!

Might as well be glass packed into these!

Last edited by mikellucci; 06-04-12 at 09:18 AM.

#63

Yes because I rebuilt the C1 with ceramic $$$ bearings on the impeller shaft. The compressor is actually a bit smaller on the C1 vs C2. Needless to say the C1 is in a garbage bag in the corner of my garage after what happened to it a few weeks back. lol

Might as well be glass packed into these!

Might as well be glass packed into these!

#64

Interesting story, it seems like a lot of superchargers have bearing problems. I had a supercharged scion tc at one point and the bearings were always failing on the shaft side of the unit. I came to the same conclusion as you though, i don't recommend ceramic bearings in the s/c. I just tell people to change out the standard bearings after x amount of time. Good luck with the build though, i didn't realize the stock ecu can compensate for that much boost.

Those are my conclusions at this point as well - Deal with an easy rebuild after XXk miles using ABEC-7 bearings and not ceramic.

Did you use a "Procharger" unit on your Scion? I would think this same logic applies to many bearing / gear driven S/C's. I have no idea how people run over 15 psi on some superchargers and dont have to rebuild their units until 20k miles down the road..

I've been looking at Raptor and Rotrex S/Cs more recently...I'm still not convinced they are that much better over the long haul.

#65

Thanks for chiming in!

Those are my conclusions at this point as well - Deal with an easy rebuild after XXk miles using ABEC-7 bearings and not ceramic.

Did you use a "Procharger" unit on your Scion? I would think this same logic applies to many bearing / gear driven S/C's. I have no idea how people run over 15 psi on some superchargers and dont have to rebuild their units until 20k miles down the road..

I've been looking at Raptor and Rotrex S/Cs more recently...I'm still not convinced they are that much better over the long haul.

Those are my conclusions at this point as well - Deal with an easy rebuild after XXk miles using ABEC-7 bearings and not ceramic.

Did you use a "Procharger" unit on your Scion? I would think this same logic applies to many bearing / gear driven S/C's. I have no idea how people run over 15 psi on some superchargers and dont have to rebuild their units until 20k miles down the road..

I've been looking at Raptor and Rotrex S/Cs more recently...I'm still not convinced they are that much better over the long haul.

#66

Do you know how valuable those wave washers are sitting on top of the bearings (mount into casing)? I've read mixed opinions on their purpose and how necessary they truly are.

The difference with the C1/C2 impeller shaft (aside from being fragile) is it uses that giant 6009 bearing as well for a total of 3... A bearing inside of a flange inside of a bearing then of course the bearing on the end of the shaft. That makes me say WTF

The pulley shaft on the other hand is very straight forward and stout. From a novice perspective I can see why the pulley side never fails...the impeller side always goes first! lol

#67

Just thought I'd share...learned the true importance of wave springs.

Wave Springs eliminate play and minimize bearing noise. The constant light/medium pressure they apply removes play between the ball bearings and the bearings’ inner and outer races. Preloading can reduce the possibility of bearing damage due to vibration (vibratory loading) and wear due to repetitive and non-repetitive runout.

Wave Springs eliminate play and minimize bearing noise. The constant light/medium pressure they apply removes play between the ball bearings and the bearings’ inner and outer races. Preloading can reduce the possibility of bearing damage due to vibration (vibratory loading) and wear due to repetitive and non-repetitive runout.

#68

^Interesting. Reminds me of when I had to shim my Honda trans for a Quaife LSD and I bought like 4 different shims to set the exact pre-load I wanted. After time though I would figure that wave spring would start to increase the amount of play/preload and cause problems.

#69

^Interesting. Reminds me of when I had to shim my Honda trans for a Quaife LSD and I bought like 4 different shims to set the exact pre-load I wanted. After time though I would figure that wave spring would start to increase the amount of play/preload and cause problems.

#71

Look closer, my fmic is a treadstone, larger then the LMS and efficient as all hell.

#72

Havent been driving my car much and traveling a lot with work. I've been thinking more about vacuum source and the performace of the blow off valve with the changes I made over the last month or so. I still do not like the flutter I'm hearing at 0-2psi even though above that blows off cleanly.

Dug up some old info. and view points of members past including a post from Synapse. First things first I think I'm going to drill and tap a new spot on the intake manifold to pull pressure from for the BOV.

I'm T'd here for bov only right now.

Where as Elias (pepos) tapped his own-

Here is a picture of the Vacuum for the Synapse.

I also removed from the inside of BOV the small preload spring and attached to Vacuum source both ports A & B.

Now the BOV works like a charm.

Stays open at idle and light throttle closes when it senses boost and opens again when i step off without fluttering or surge.

Taking VAC/Boost from the already existing port that the manifold has didn't work well.

Perhaps it's not free and it restricts the signal somehow.

I'm only using that right now to feed the PLX Boost and AFR device.

Synapse provided some insight years ago with the following-

Hey boys, I'm glad that you're seeing first hand the benefits of the Synchronic design on your SC system. I watched the videos and have a couple of tips that will make the BOV work, about 100% better for your application.

Please connect the 3rd port (Port C) to a boost-only source. Do not, use a check valve to a vacuum source as it will trap pressure. Try to gett boost-only from one of the charge pipes, or perhaps a threaded fitting on the compressor housing.

Once you have boost-only connected, play around with different hose combinations of the vac hoses on the back. You have 3 possible combinations, both hoses, and 2 with only either hose on the back connected.

Give these things a try and you should see some marked improvements.

These are improvement areas for me that I hope to achieve in the near future.

Dug up some old info. and view points of members past including a post from Synapse. First things first I think I'm going to drill and tap a new spot on the intake manifold to pull pressure from for the BOV.

I'm T'd here for bov only right now.

Where as Elias (pepos) tapped his own-

Here is a picture of the Vacuum for the Synapse.

I also removed from the inside of BOV the small preload spring and attached to Vacuum source both ports A & B.

Now the BOV works like a charm.

Stays open at idle and light throttle closes when it senses boost and opens again when i step off without fluttering or surge.

Taking VAC/Boost from the already existing port that the manifold has didn't work well.

Perhaps it's not free and it restricts the signal somehow.

I'm only using that right now to feed the PLX Boost and AFR device.

Synapse provided some insight years ago with the following-

Hey boys, I'm glad that you're seeing first hand the benefits of the Synchronic design on your SC system. I watched the videos and have a couple of tips that will make the BOV work, about 100% better for your application.

Please connect the 3rd port (Port C) to a boost-only source. Do not, use a check valve to a vacuum source as it will trap pressure. Try to gett boost-only from one of the charge pipes, or perhaps a threaded fitting on the compressor housing.

Once you have boost-only connected, play around with different hose combinations of the vac hoses on the back. You have 3 possible combinations, both hoses, and 2 with only either hose on the back connected.

Give these things a try and you should see some marked improvements.

These are improvement areas for me that I hope to achieve in the near future.

#73

Hmm looks like you found some good info!

On a side note, I'll be receiving the LMS kit from you today, says FedEx. And i opted for my shop to install it... So it'll be getting installed tomorrow and Friday. I may direct their attention to this thread and others for any background and troubleshooting haha. :

I may direct their attention to this thread and others for any background and troubleshooting haha. :

On a side note, I'll be receiving the LMS kit from you today, says FedEx. And i opted for my shop to install it... So it'll be getting installed tomorrow and Friday.

I may direct their attention to this thread and others for any background and troubleshooting haha. :

I may direct their attention to this thread and others for any background and troubleshooting haha. :

#74

Hmm looks like you found some good info!

On a side note, I'll be receiving the LMS kit from you today, says FedEx. And i opted for my shop to install it... So it'll be getting installed tomorrow and Friday. I may direct their attention to this thread and others for any background and troubleshooting haha. :

I may direct their attention to this thread and others for any background and troubleshooting haha. :

On a side note, I'll be receiving the LMS kit from you today, says FedEx. And i opted for my shop to install it... So it'll be getting installed tomorrow and Friday.

I may direct their attention to this thread and others for any background and troubleshooting haha. :

I may direct their attention to this thread and others for any background and troubleshooting haha. : I would likely advise them or get their input around adding a better port on the intake manifold for pressure though. I think I'm going to tap one similar to Elias above!

I would likely advise them or get their input around adding a better port on the intake manifold for pressure though. I think I'm going to tap one similar to Elias above!Just tell em to look at my pics, I gave you the same spacers I had machined for the studs and the 2 tensioner pulleys. Its all together on the bracket but they'll have to undo it when installing of course. Take pics!

#75

Are you tee'd inline with the evap clicky valve? They had the same setup in my scion tc with the trd supercharger and I changed it over to a much bigger and more isolated vacuum source also. I thought my bov became slightly more responsive after that change over, but might have just been in my head, i had an hks ssqv.

Havent been driving my car much and traveling a lot with work. I've been thinking more about vacuum source and the performace of the blow off valve with the changes I made over the last month or so. I still do not like the flutter I'm hearing at 0-2psi even though above that blows off cleanly.

Dug up some old info. and view points of members past including a post from Synapse. First things first I think I'm going to drill and tap a new spot on the intake manifold to pull pressure from for the BOV.

I'm T'd here for bov only right now.

Where as Elias (pepos) tapped his own-

Here is a picture of the Vacuum for the Synapse.

I also removed from the inside of BOV the small preload spring and attached to Vacuum source both ports A & B.

Now the BOV works like a charm.

Stays open at idle and light throttle closes when it senses boost and opens again when i step off without fluttering or surge.

Taking VAC/Boost from the already existing port that the manifold has didn't work well.

Perhaps it's not free and it restricts the signal somehow.

I'm only using that right now to feed the PLX Boost and AFR device.

Synapse provided some insight years ago with the following-

Hey boys, I'm glad that you're seeing first hand the benefits of the Synchronic design on your SC system. I watched the videos and have a couple of tips that will make the BOV work, about 100% better for your application.

Please connect the 3rd port (Port C) to a boost-only source. Do not, use a check valve to a vacuum source as it will trap pressure. Try to gett boost-only from one of the charge pipes, or perhaps a threaded fitting on the compressor housing.

Once you have boost-only connected, play around with different hose combinations of the vac hoses on the back. You have 3 possible combinations, both hoses, and 2 with only either hose on the back connected.

Give these things a try and you should see some marked improvements.

These are improvement areas for me that I hope to achieve in the near future.

Dug up some old info. and view points of members past including a post from Synapse. First things first I think I'm going to drill and tap a new spot on the intake manifold to pull pressure from for the BOV.

I'm T'd here for bov only right now.

Where as Elias (pepos) tapped his own-

Here is a picture of the Vacuum for the Synapse.

I also removed from the inside of BOV the small preload spring and attached to Vacuum source both ports A & B.

Now the BOV works like a charm.

Stays open at idle and light throttle closes when it senses boost and opens again when i step off without fluttering or surge.

Taking VAC/Boost from the already existing port that the manifold has didn't work well.

Perhaps it's not free and it restricts the signal somehow.

I'm only using that right now to feed the PLX Boost and AFR device.

Synapse provided some insight years ago with the following-

Hey boys, I'm glad that you're seeing first hand the benefits of the Synchronic design on your SC system. I watched the videos and have a couple of tips that will make the BOV work, about 100% better for your application.

Please connect the 3rd port (Port C) to a boost-only source. Do not, use a check valve to a vacuum source as it will trap pressure. Try to gett boost-only from one of the charge pipes, or perhaps a threaded fitting on the compressor housing.

Once you have boost-only connected, play around with different hose combinations of the vac hoses on the back. You have 3 possible combinations, both hoses, and 2 with only either hose on the back connected.

Give these things a try and you should see some marked improvements.

These are improvement areas for me that I hope to achieve in the near future.