End link bent in half....lol what a piece.

#32

Yeah, I think I hit the perfect combo of tight turn at night, and pothole. It was the pothole thump sound and then POW went the nut. Obviously overstressed it. My guess is the end link bent and the nut couldn't withstand the continued pressure of the turn and funny angle. It's dark outside and late. I'll have a closer look in the morning.

I am going to have to settle down on my driving habits. Minnesota in the springtime, ya know? Probably like Jeff said, he's bent many end links because of driving too hard for the conditions. The hole only serves to focus all the stress instantaneously on that one part.

Live and learn. We can't expect engineers to design everything perfectly. Question is, if the end link were 2-3 times as strong, what would be the next part in the chain to fail? The one guy said it was probably designed to fail so some more expensive part didn't.

I am going to have to settle down on my driving habits. Minnesota in the springtime, ya know? Probably like Jeff said, he's bent many end links because of driving too hard for the conditions. The hole only serves to focus all the stress instantaneously on that one part.

Live and learn. We can't expect engineers to design everything perfectly. Question is, if the end link were 2-3 times as strong, what would be the next part in the chain to fail? The one guy said it was probably designed to fail so some more expensive part didn't.

#33

Its designed to bend. The stiffer the endlinks, the more brittle it becomes if you break it. For suspension parts, you dont want it to be too stuff because the link will break without warning. There needs to be a balance between the two. If you make your endlinks too strong, your bar will be the one that may snap (they're stiffer than OEM).

This is why I do not like the Daizen design at all. When the endlinks are flipped around, it sits at a slight angle so as you turn, there is some horizontal force acting on the nut. Too much of it, the nut will pop out. Guess how many nuts I've lost. Now I'm back to OEM sways..

This is why I do not like the Daizen design at all. When the endlinks are flipped around, it sits at a slight angle so as you turn, there is some horizontal force acting on the nut. Too much of it, the nut will pop out. Guess how many nuts I've lost. Now I'm back to OEM sways..

#35

Lexus Test Driver

Its designed to bend. The stiffer the endlinks, the more brittle it becomes if you break it. For suspension parts, you dont want it to be too stuff because the link will break without warning. There needs to be a balance between the two. If you make your endlinks too strong, your bar will be the one that may snap (they're stiffer than OEM).

This is why I do not like the Daizen design at all. When the endlinks are flipped around, it sits at a slight angle so as you turn, there is some horizontal force acting on the nut. Too much of it, the nut will pop out. Guess how many nuts I've lost. Now I'm back to OEM sways..

This is why I do not like the Daizen design at all. When the endlinks are flipped around, it sits at a slight angle so as you turn, there is some horizontal force acting on the nut. Too much of it, the nut will pop out. Guess how many nuts I've lost. Now I'm back to OEM sways..

Henry, have you tried using lock washers?

#36

LOL I knew someone would say something about that

I've used lock washers and to be honest, even they dont work quite as well, especially since the Daizen bar is metal itself. It's not soft enough for the washer to dig into.

I even went as far as using loctite, but eventually it would fall out. I'm using OEM sways right now and I have no problem whatsoever.

I've used lock washers and to be honest, even they dont work quite as well, especially since the Daizen bar is metal itself. It's not soft enough for the washer to dig into.

I even went as far as using loctite, but eventually it would fall out. I'm using OEM sways right now and I have no problem whatsoever.

#37

Lexus Champion

iTrader: (10)

This thread is from way back, threes years ago, lol...but anyways...

I don't know if Jeff ever followed through with this or not but from what I gathered from his description he was talking about more or less making a "tube" style brace or sheath if you will, to cover the oem part and then weld it. That method would work but I think it would be overkill and difficult to produce as you would need to have a bandsaw or something to do a relatively precise cut down the longitudinal axis of the brace piece which would be a PITA to do properly. I would suggest just taking a few lengths of steel tubing and tacking them onto the factory part in 3 places or so, it doesn't need to be a full weld as all you are doing is trying to prevent buckling/raise the shear strength of the endlink and that bracing would be plenty IMO.

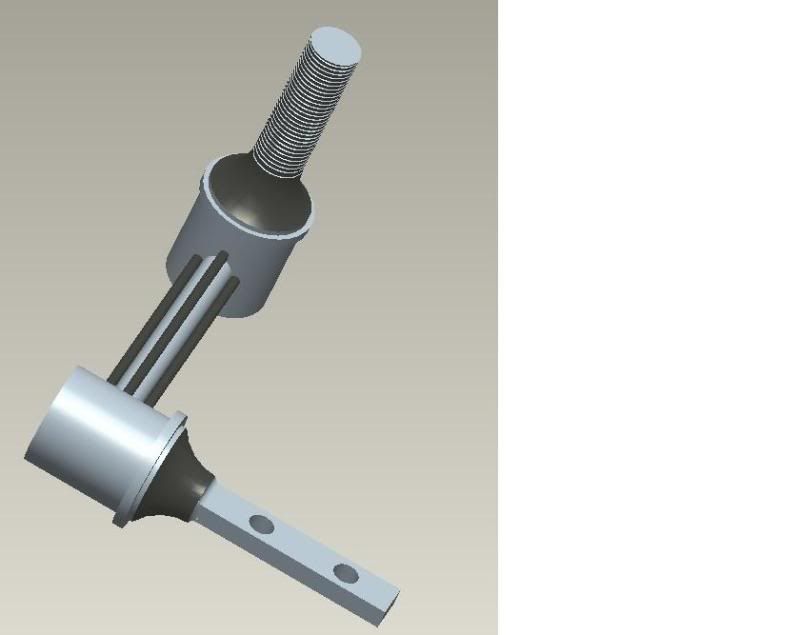

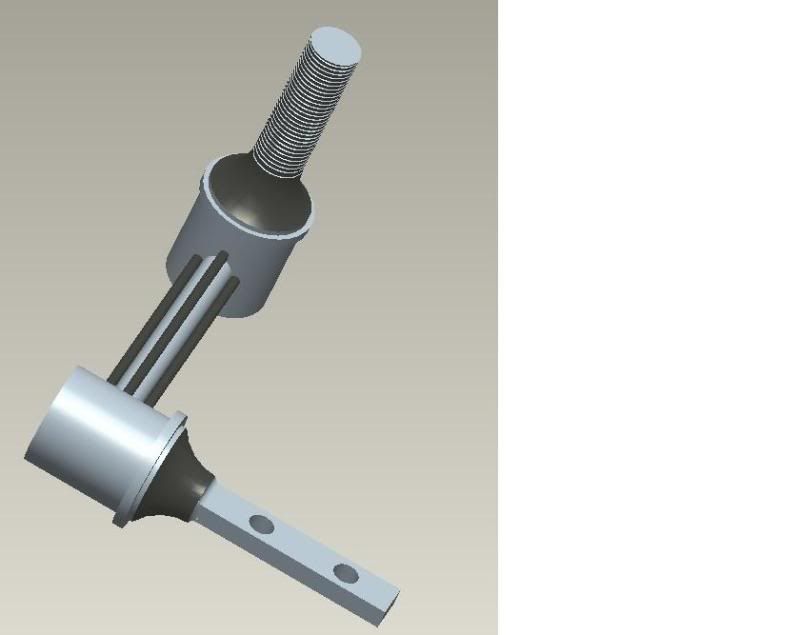

I modeled up what I'm talking about so people can get a better idea, it would be two minutes to just tack on a few braces and you wouldnt have to worry about the heat etc...ruining the endlink as it would just be a split second to tack each brace on.

Standard Endlink:

"Tube" Braced Endlink:

My suggestion:

I don't know if Jeff ever followed through with this or not but from what I gathered from his description he was talking about more or less making a "tube" style brace or sheath if you will, to cover the oem part and then weld it. That method would work but I think it would be overkill and difficult to produce as you would need to have a bandsaw or something to do a relatively precise cut down the longitudinal axis of the brace piece which would be a PITA to do properly. I would suggest just taking a few lengths of steel tubing and tacking them onto the factory part in 3 places or so, it doesn't need to be a full weld as all you are doing is trying to prevent buckling/raise the shear strength of the endlink and that bracing would be plenty IMO.

I modeled up what I'm talking about so people can get a better idea, it would be two minutes to just tack on a few braces and you wouldnt have to worry about the heat etc...ruining the endlink as it would just be a split second to tack each brace on.

Standard Endlink:

"Tube" Braced Endlink:

My suggestion:

#39

Holy crap, you spent the time to draw up those diagram?!? Props to you if you did

Did you use Solidworks?

As for me pursuing the design further I didn't find it to be necessary. The reason these endlinks get stressed to the point of breakage is due to mismatched suspension parts. For example if you run TRD sways on a OEM suspension, the sways will take a huge brunt of the force of keeping the car flat through corners. On my car I currently have Tein Flex along with TRD sways and the two compliment each other. Both are relatively stiff and work with each outher. When I bent the endlinks I believe I was running the OE suspension with the TRD sways.

Did you use Solidworks?

As for me pursuing the design further I didn't find it to be necessary. The reason these endlinks get stressed to the point of breakage is due to mismatched suspension parts. For example if you run TRD sways on a OEM suspension, the sways will take a huge brunt of the force of keeping the car flat through corners. On my car I currently have Tein Flex along with TRD sways and the two compliment each other. Both are relatively stiff and work with each outher. When I bent the endlinks I believe I was running the OE suspension with the TRD sways.

Last edited by JeffTsai; 04-08-09 at 11:38 PM.

#40

Lexus Champion

iTrader: (10)

I was bored one night so I modeled them up, I used Pro-Engineer (Wildfire 4) to model them, wasn't too bad though, took me about 45 min or so. I just made the original (oem) part and then added the bracing to it in an assembly. I would have run an FEA analysis (Von Mises graph would be cool to see) on it just for kicks but I only have the student edition of Pro-E at my house and it doesn't include Mechanica, and doing it by hand isn't worth the time and too much effort, lol. I'll do that at work when I'm getting paid to do FEA by hand.

Also to anyone reading this who may pursue it, the last model with four braces was just to give an idea, the end link is pretty small so you would really only need two braces 90 degrees apart from each other, that should suffice. Make sure they are 90 degrees apart, not 180 degrees as that primarily would only help bending in one direction, 90 degrees apart will give it extra strength in both front/back and side/side directions.

Also to anyone reading this who may pursue it, the last model with four braces was just to give an idea, the end link is pretty small so you would really only need two braces 90 degrees apart from each other, that should suffice. Make sure they are 90 degrees apart, not 180 degrees as that primarily would only help bending in one direction, 90 degrees apart will give it extra strength in both front/back and side/side directions.

Last edited by macd7919; 04-09-09 at 12:54 AM.

#41

Lexus Champion

iTrader: (3)

Just wondering if anything ever came out of the upgraded end links. I was changing my oil the other day and noticed that the rear Daizen bar was disconnected on one side and the nut was gone. And I dont drive through the corners all that hard.

After reading Gstegs post, Im thinking about putting the stock rear bar back on, and maybe stiffening the rear chassis a bit by adding a rear underbody brace?

Also, I will not drop the car so stiffer spring or coilovers are not an option, but what if I just got a set of billstein sport shocks to go along with stock springs?

After reading Gstegs post, Im thinking about putting the stock rear bar back on, and maybe stiffening the rear chassis a bit by adding a rear underbody brace?

Also, I will not drop the car so stiffer spring or coilovers are not an option, but what if I just got a set of billstein sport shocks to go along with stock springs?

Thread

Thread Starter

Forum

Replies

Last Post